Dynamic simulations

Our dynamic plant simulations offer a variety of benefits in testing new control concepts, in operator training or also in a software FAT during the commissioning of a new control system.

The system simulation (as a digital twin) can be coupled with different control systems. We use the appropriate software packages and combination options such as Mimic/Emerson DeltaV, Simit/Siemens and Matlab for further control system software solutions.

Optimally, the user interface is a copy of the control system. Thus, practically no difference to the real plant is recognisable. We create your processes based on our process engineering know-how and our extensive experience in consultation with your process experts.

For existing systems, we also use historical data and can adapt the simulation very well to the real system using model identification.

I am happy to be there for you!

Lukas Haffner is your expert when it comes to dynamic simulations!

Concrete examples

Simulation of an exhaust air desulphurisation plant for FAT software

The commissioning of the new control system had to take place during operation, as a plant shutdown means production downtime. In order to test the control system for commissioning as well as possible in advance, a software FAT was carried out with a simulation. This enabled all programming errors to be found and control concepts to be modified so that commissioning could be mastered without any problems during operation.

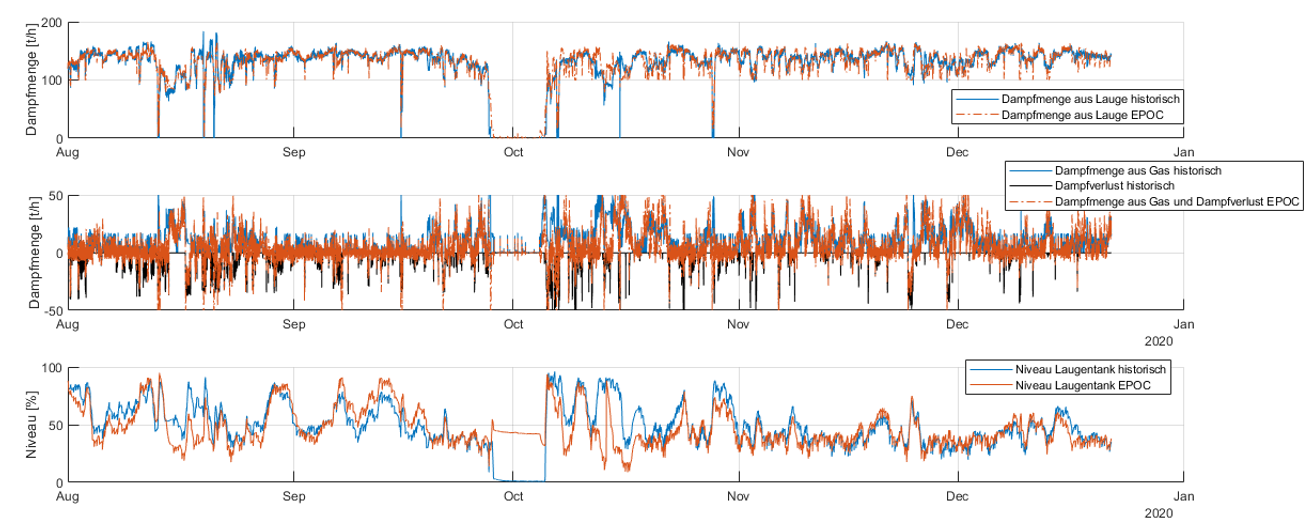

Simulation of the calculated savings

In order to validate the new EPOC Steammanager control concept in advance and to estimate the economic potential, a Matlab simulation was created and compared with historical data. It was shown that the control concept meets the requirements of the operation with the occurring steam fluctuations of the steam consumers, which was subsequently confirmed during commissioning.