Plant conversion (turnkey)

Shaping technology for the future together!

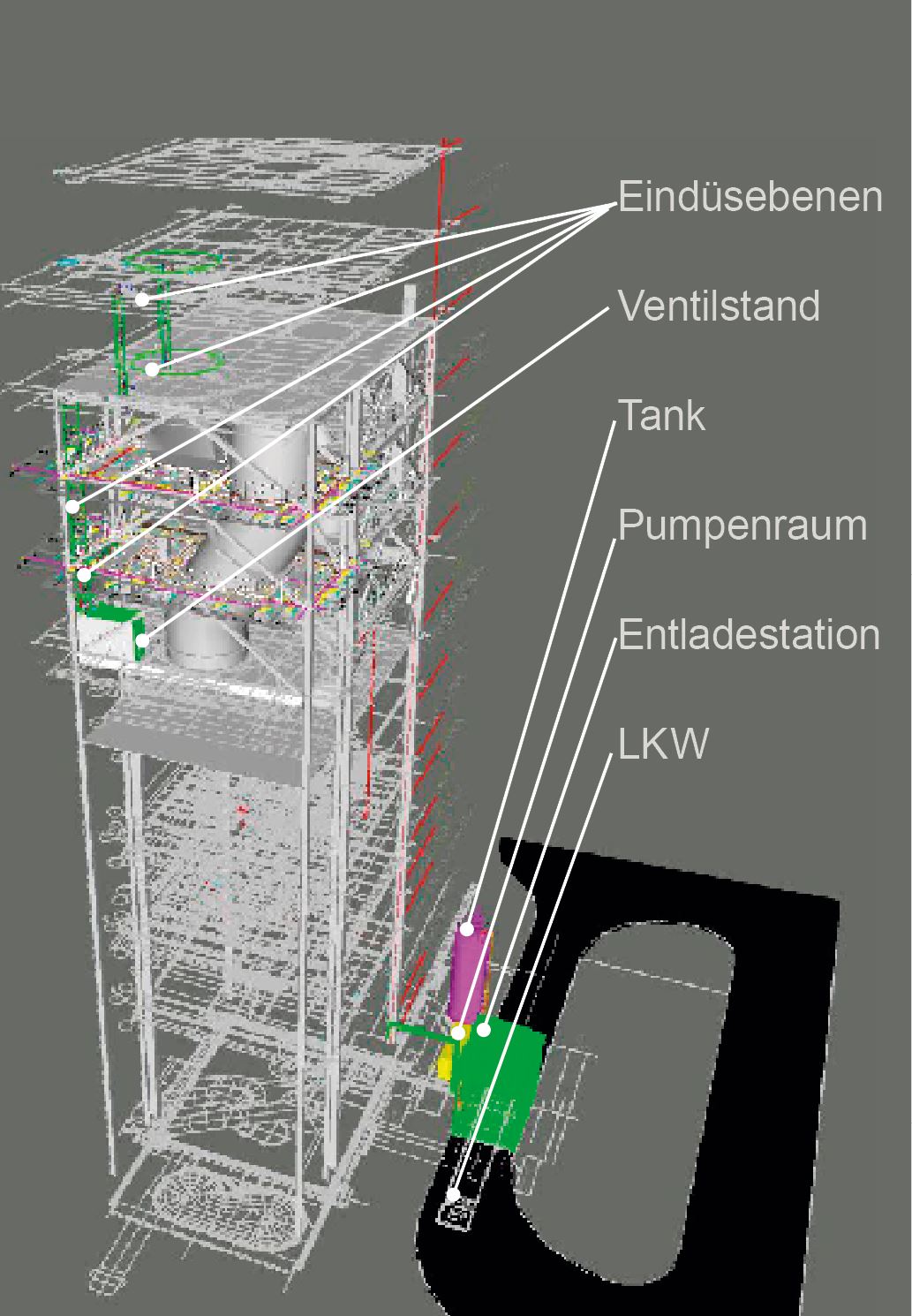

Optimisation often requires plant adaptations of varying depth. Based on analyses, studies and concepts, which we also design as a basis for control improvements, we also implement specific necessary plant conversions.

We always pursue the approach of upgrading systems as minimally invasively as possible right from the initial studies and concepts. Many steps are possible through control technology and digitalisation.

But if necessary, we also rebuild. In doing so, we adapt as well as possible to the client’s ideas. Depending on requirements, we act as a general contractor or focus on core service areas in the implementation and pay attention to the optimal integration of service components provided by the client in the technology work, engineering and project support.

Our aim is to work with you to find the best possible solution. So don’t hesitate to contact us and benefit from our expertise!

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Dominik Gappmaier is your expert when it comes to system conversion!

Plant conversion (turnkey)

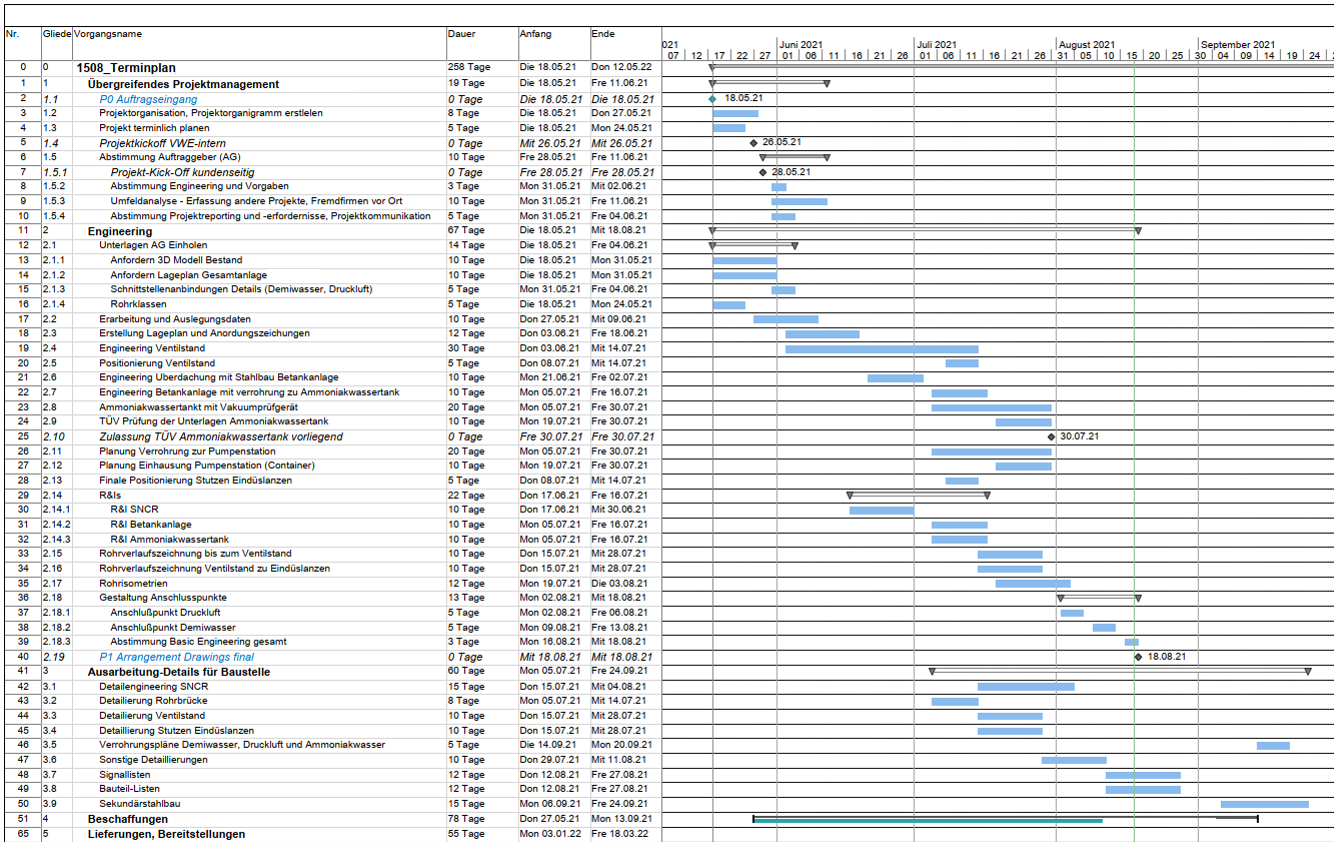

The focus is on the operational restrictions (revision time window, minimization of downtimes, existing topology) and the requirement to create the best possible optimization in a “minimally invasive” manner. Compact project management for optimal coordination goes without saying.

This approach means that we can cover a range of very small conversion work for you, such as the addition and upgrading of sensors and actuators, through to general contractor contracts with a volume of several million euros.

Of course, we also supply our SNCR system with Artificial Intelligence technology as a complete solution at a fixed price.

Working in existing systems and optimizing andusing the existing configuration as economically and  ecologically as possibleis not the exception but the rule for us.

ecologically as possibleis not the exception but the rule for us.

Our approach saves you costs, time and resources and often enables you to use your plant for a significantly longer period of time in an economically and ecologically sensible manner. This also makes sense in terms of circular economy considerations.

We do not see ourselves as “classic plant constructors” but as specialists for customised optimisations that also require conversion work. Accordingly, we always focus on optimising and improving the plant in all implementation steps.

For execution and implementation, we work either with local partners on site or with long-standing specialized partners who share our understanding of quality.

For us, plant conversion also includes

– On-site survey and as-built documentation

– The entire implementation including procurement, installation and commissioning

– CE marking and documentation

– Project management

Regardless of whether you already have concrete ideas or are still in the idea phase or concept development – we are happy to support you in an initial exchange. We look forward to hearing from you!

Further information: