Potential studies

Potential studies are carried out for existing systems and are the first phase of cooperation with our customers in many of our projects. The focus here is on process engineering and control engineering degrees of freedom in order to analyze these in process plants and make them usable in a further step.

![]() The more detailed the available historical process data is, the more precisely identified potential can be economically evaluated and compiled in a structured report. There is also a ranking of the identified risks, the optimization period and a cost estimate for the respective measures. This creates a solid basis for decisions on further investments. The overriding aim of a potential study carried out by us is always to improve the effectiveness and efficiency of the process or system and to minimize environmental impact, operating resources and maintenance costs.

The more detailed the available historical process data is, the more precisely identified potential can be economically evaluated and compiled in a structured report. There is also a ranking of the identified risks, the optimization period and a cost estimate for the respective measures. This creates a solid basis for decisions on further investments. The overriding aim of a potential study carried out by us is always to improve the effectiveness and efficiency of the process or system and to minimize environmental impact, operating resources and maintenance costs.

The CONENGA Group has extensive expertise in carrying out potential studies for various process engineering systems across multiple industries. From the food industry and the chemical industry to one of our focus areas, the energy industry, we develop solution to various problems.

With our expertise, we stand for one thing above all: the optimal interaction of process engineering, control technology and digitalization solutions. This results in a series of findings and insights that often reveal new approaches to our customers and ensure feasible options for implementation.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

The diversity of potential

Environmental friendliness and identification of potential energy savings

The potential studies help to uncover energy losses and inefficient energy use in process plants and identify specific measures to save energy.

Optimizing the energy efficiency of process plants can also have a positive impact on the environment, e.g. by reducing energy consumption and emissions.

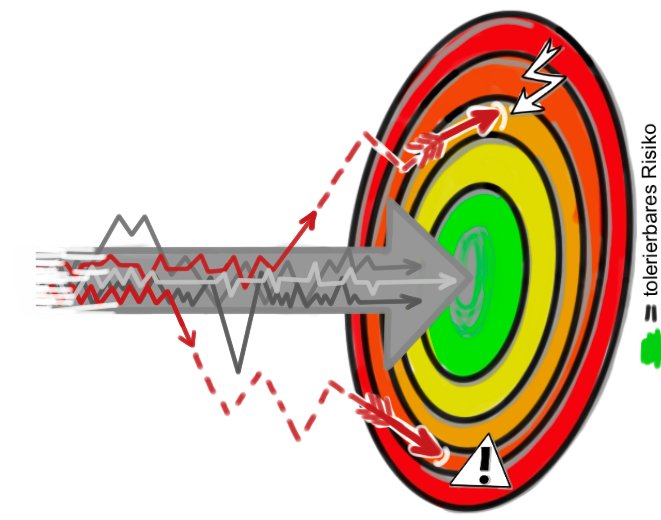

Optimization of process engineering and improvement of control engineering

A detailed process data analysis identifies weak points and areas that can be optimized. Realizing this potential will lead to improved process control, product quality and efficiency.

When considering the control performance, the parameter settings and the oscillation behavior of individual controllers are analyzed. After controller tuning, process systems can be operated more dynamically, more stably and with better performance. This also leads to higher product quality and efficiency.

Increasing competitiveness

An optimized process plant with an efficient use of energy and low operating resources leads to improved product quality and thus to improved competitiveness of a company

The exact results and findings of a potential study depend heavily on the specific conditions of the process plant. An individual analysis and expertise are required to identify specific and customized optimization options. In general, however, it can be said that the total amount of energy generated annually is the key parameter for the economic viability of measures to increase efficiency.

potential study depend heavily on the specific conditions of the process plant. An individual analysis and expertise are required to identify specific and customized optimization options. In general, however, it can be said that the total amount of energy generated annually is the key parameter for the economic viability of measures to increase efficiency.

Because smaller energy systems often cannot keep up with the automation technology (sensors, control, process data, etc.) or the human resources of larger systems, optimization potential is rarely identified. However, if these are identified and exploited, they are often larger in percentage terms and certainly make an economic optimization project possible. A second, more precise expert view can therefore be of great benefit.

Communication creates clarity

Clarity, traceability and trust are key success factors in the implementation of potential analyses and optimization projects. In order to ensure the necessary common understanding of the system, good communication, intensive exchange and comprehensible documentation of the process engineering relationships and possibilities are important to us. Identified potentials and their evaluation are professionally derived by our engineers, underpinned with balance sheets or simulations and presented in a comprehensible manner using graphical representations.

key success factors in the implementation of potential analyses and optimization projects. In order to ensure the necessary common understanding of the system, good communication, intensive exchange and comprehensible documentation of the process engineering relationships and possibilities are important to us. Identified potentials and their evaluation are professionally derived by our engineers, underpinned with balance sheets or simulations and presented in a comprehensible manner using graphical representations.