Sorption process

Our solutions for flue gas cleaning minimise your use of operating materials (e.g. lime additives or activated coke) in your plants. This also enables you to greatly reduce the quantities of cost-intensive residues from flue gas cleaning (e.g. filter ash) that have to be disposed of.

Services

- Analysis of status (plant, emission limits)

- Analysis of data

- Development of a concept

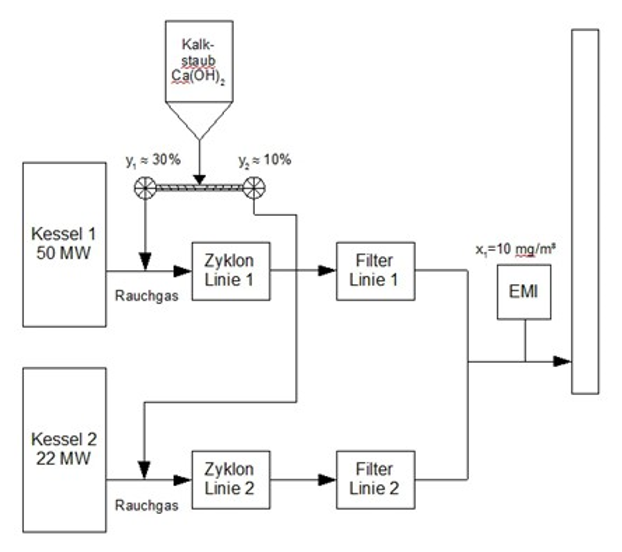

Example of a sorption process

As an example, our solution approach serves for a plant consisting of two combustion lines, a common storage tank for the absorbent Ca (OH)2and a common HCl measurement at the stack.

The aim is not to exceed the legal requirement of 10 mg/m³ HCl in the flue gas and to do so with a minimum total lime input.

This specification is achieved via model equations for HCl adsorption, which we map in a control algorithm that in turn calculates the loading (in g-HCl per g-lime) with the HCl concentration in the flue gas. Our system takes into account the process-related influencing factors for maximum lime adsorption in order to keep the total lime input to a minimum and thus also to keep disposal costs low.

Related topics

Products

Blog article on the topic