EPOC® Suite

With the EPOC® Suite will take your site to a new level of efficiency.

The interaction between energy supply, energy distribution and energy use is optimally controlled and clearly displayed with the help of definable criteria. This means you have existing and future challenges well under control.

We are here for you!

Our experts will be happy to help you optimize your systems! Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Sebastian Sturm is your expert when it comes to the EPOC® Suite!

EPOC® – Energy & Production Optimization Control

For energy-intensive industries and utilities, the challenges are changing dynamically. Scarce availability causes prices for energy sources to rise massively. The requirements of the “European Green Deal” impose additional costs (CO2 pricing) and restrictions on fossil fuels in order to reduce greenhouse gas emissions. In addition to compliance with statutory emission limits and the reduction of greenhouse gas emissions, there is also the parallel challenge of der Cost reduction by reducing the use of primary energy. More and more often, a shortage of skilled workers is also a task to be overcome when staffing the operating team.

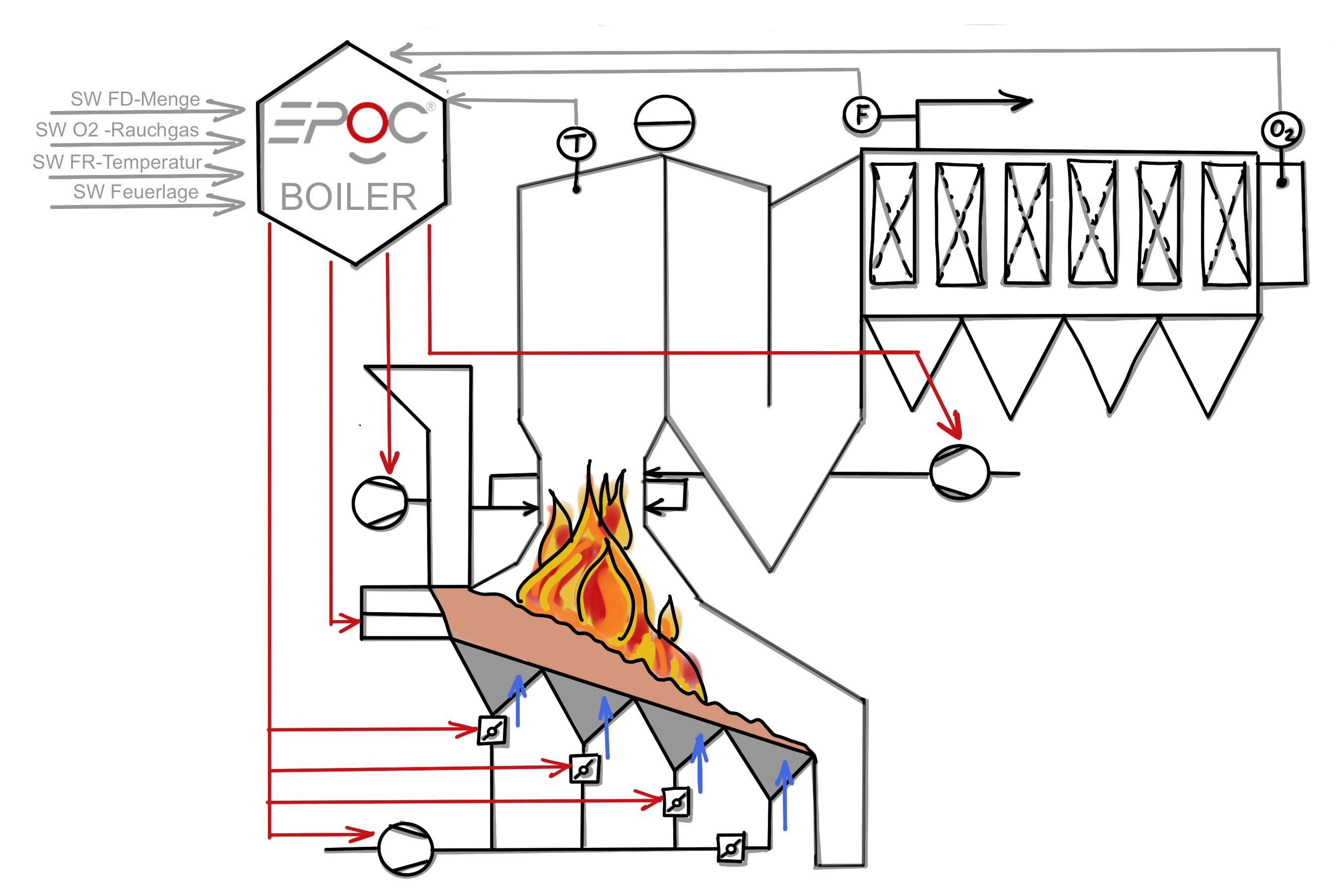

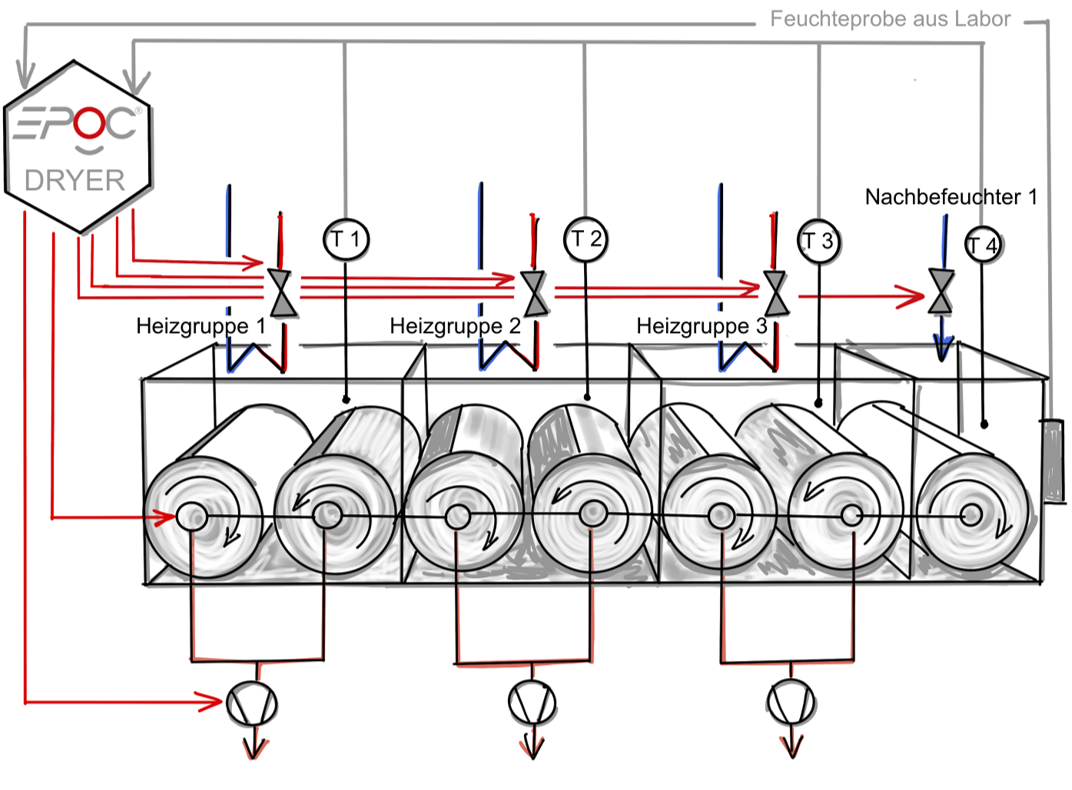

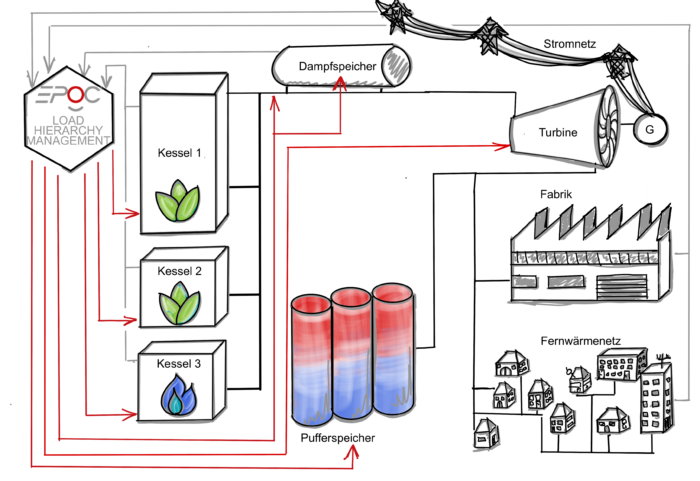

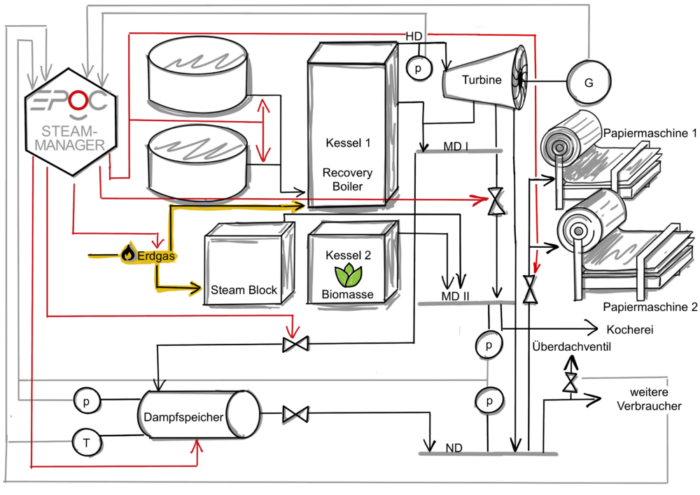

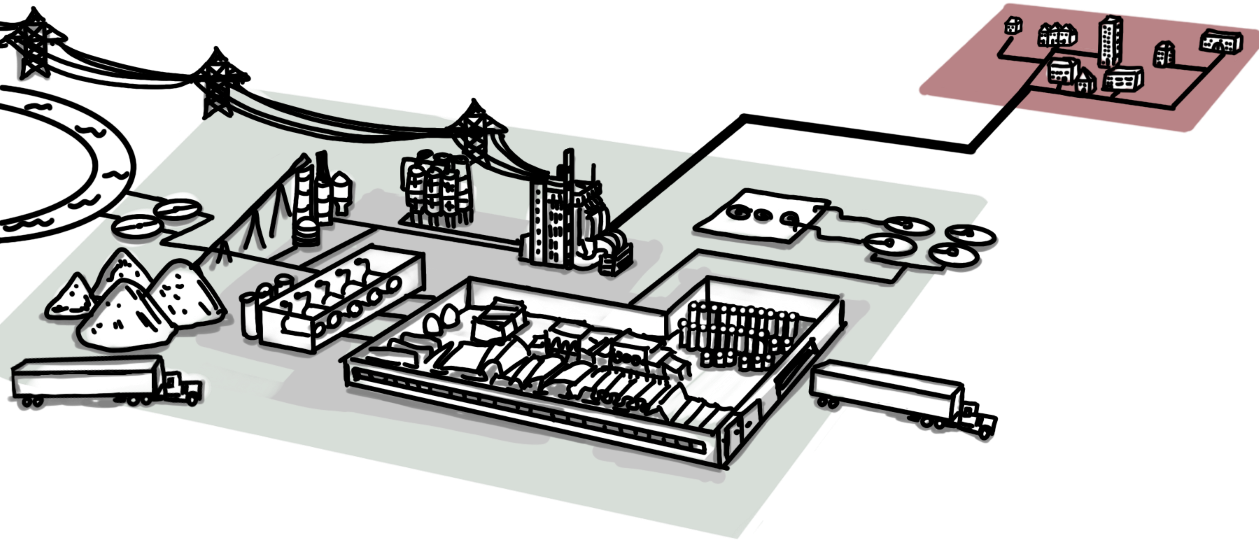

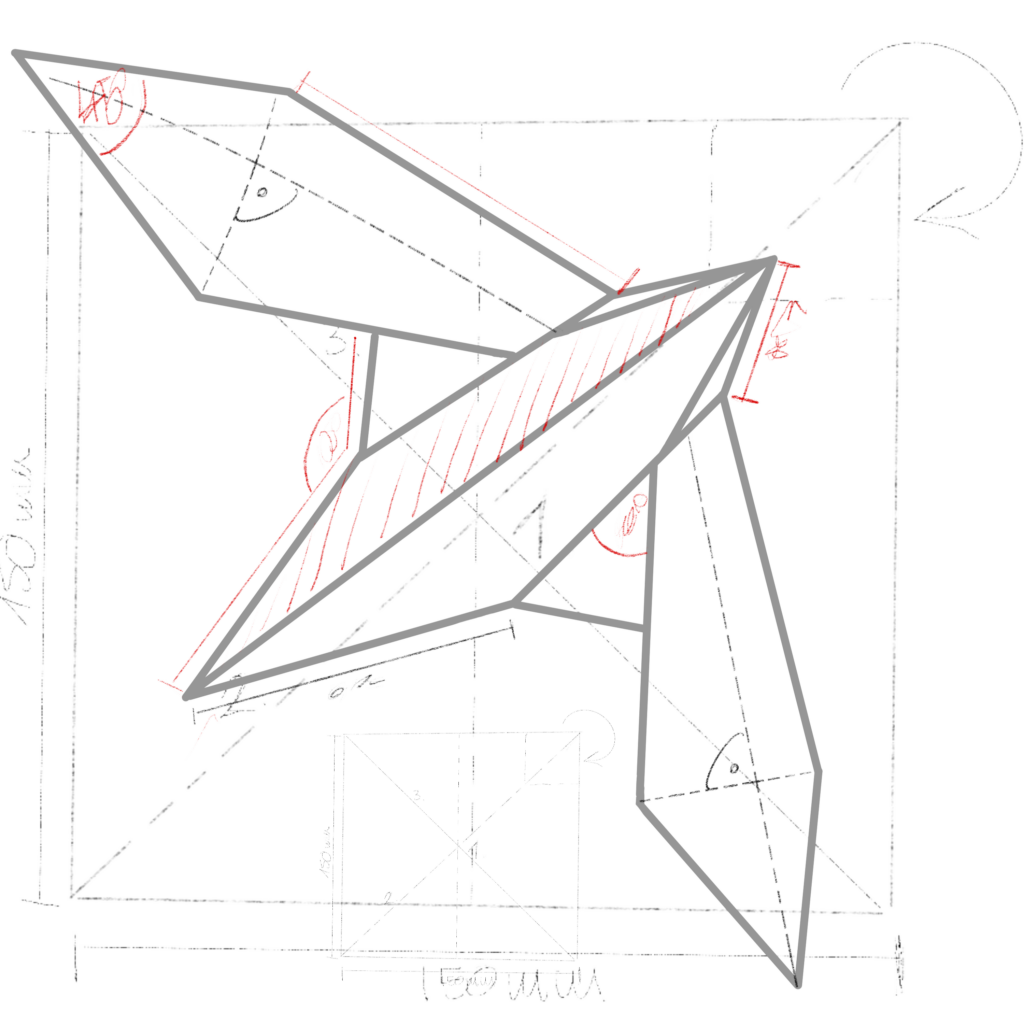

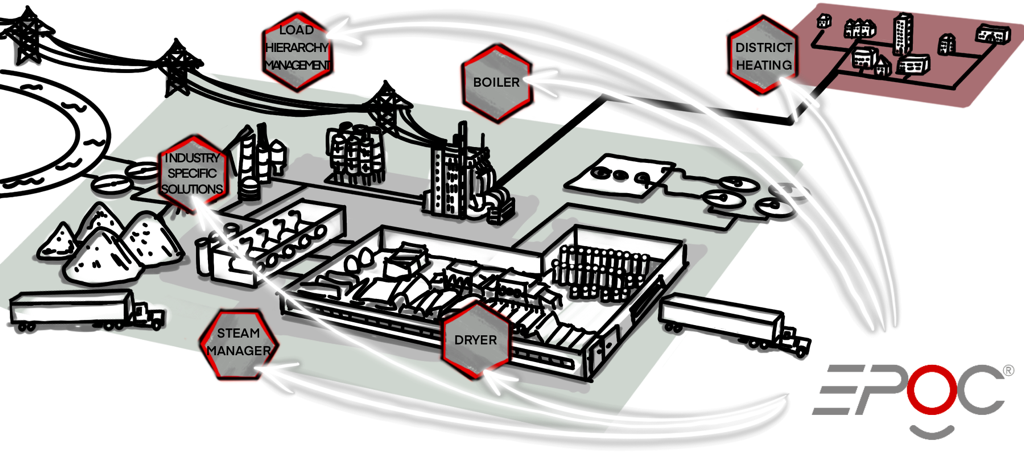

EPOC stands for “Energy & Production Optimization Control” and provides a site-wide, overarching optimization solution. With the core modules from the areas of advanced process control, simulation, energy balancing, diagnostics and monitoring, built with deep process engineering know-how, you get a comprehensive tool to achieve and maintain a maximum efficiency level and adapt to new conditions. The modules can be deployed quickly and are integrated precisely into existing systems.

The EPOC® Suite consists of six standardized process and control engineering modules and the integrated web platform for monitoring, data availability, visualization and reporting. Demand-driven implementation combines fast realization with optimal impact. You benefit from the improvement of the overall efficiency by increasing the degree of automation and the constantly efficient operation of your plants in compliance with legal requirements.

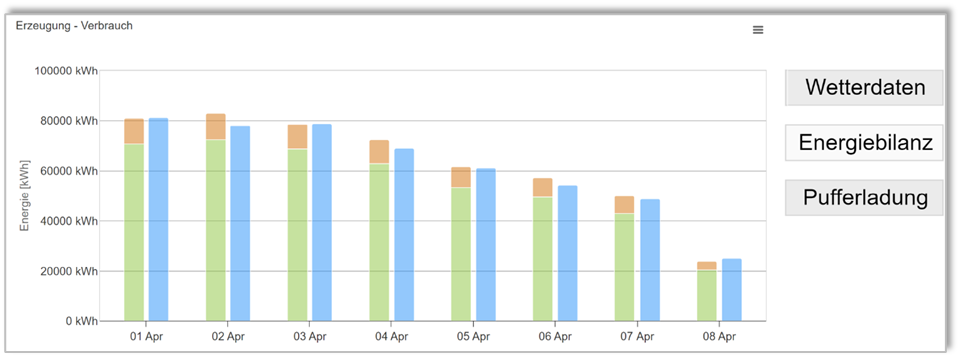

Energy demand fluctuations are optimally balanced by integrating forecast tools into the control of energy supply and distribution. Less fuel consumption, reduction of the CO2 footprint and optimization of the balance between energy supply and energy use have a direct positive effect in terms of climate protection and costs.

Smoother driving and less work due to a significant reduction in the number of manual interventions required are significant from an organizational and economic point of view. Thanks to the simplification and stabilization of (production) processes, productivity and quality are increased. The life and travel time of your equipment will be extended thanks to uniform operation.

You can download the EPOC® implementation project as an investment or without CAPEX, via a user agreement. In this case, a usage fee is served via the optimization revenues.

In both cases, the implementation is compliant with the EU Taxonomy Regulation on the achievement of climate targets (EU 2020/852). The EPOC® Cloud enables a clear presentation of your investments and the explicit identification of your contributions to climate protection.

EPOC® Suite Module

further links

Here at the site, the EPOC® Steam Manager from VOIGT+WIPP Engineers supports the optimal operation of the steam network according to economic and ecological aspects. In addition to the successful reduction of steam losses, primary energy is saved through the forward-looking consideration of production planning. The savings identified via the potential study are realized, so everyone wins – the environment and the company!”

“VOIGT+WIPP Engineers are good communicators and experts on combustion control with deep process know-how integrated in their control product EPOC® Suite. As a very reliable and self responsible partner our project could proceed according to schedule and problems were detected and solved shortly after.”

Your benefit at a glance

Integration into the inventory, topology, hardware

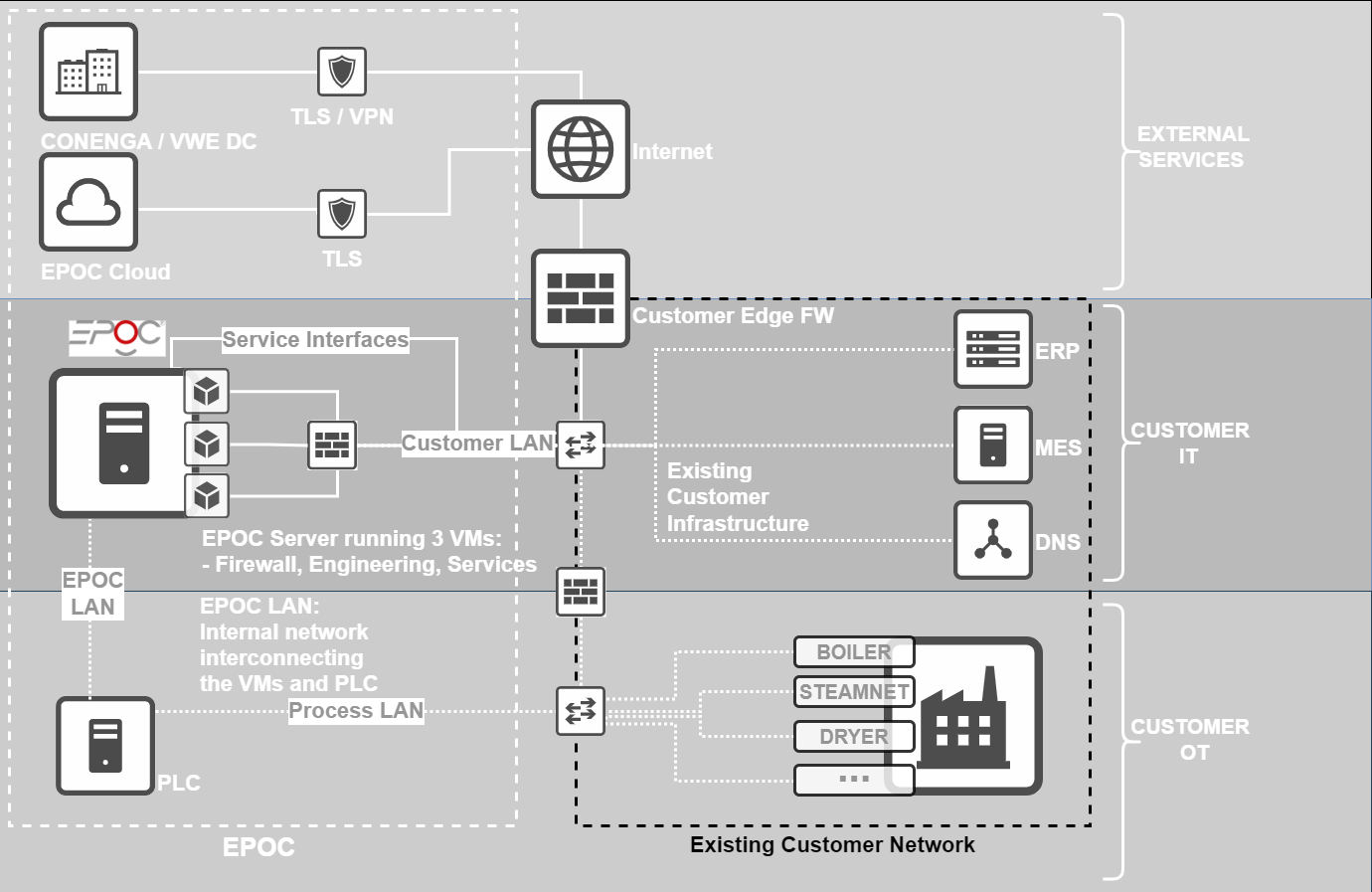

The integration of EPOC® into your IT inventory involves several levels:

- EPOC® PLC (Customer OT): Level with connection to existing control technology

- EPOC® Server (Customer IT): Engineering station, data hub for other data sources

- EPOC® Cloud (External Services): Reporting, service, monitoring, remote maintenance connection

The hardware used for the controllers (PLC) is highly available and can optionally also be designed redundantly. The connection to the existing infrastructure is carried out with the highest IT and OT security criteria. Between the inventory and EPOC® there is a signal tracking system that enables skip-free switching. The signal switching is implemented together with the I&C programmer responsible for the site.

EPOC®-HMI

Our modern HMI provides you with a clear overview of all the important data.

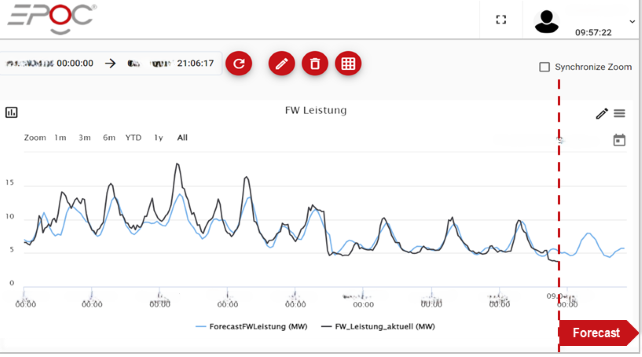

In addition to energy balances, current predictions can also be made for model-based

process values as well as for the expected production process can be visualized.