SNCR-Plant with AI Technologie

Compliance with emission limits has become indispensable due to the legal framework conditions, and achieving ever lower values will keep us busy for a long time to come. We know what is important when implementing selective non-catalytic reduction (SNCR) denitrification plants for your site and we implement this turn-key for our customers.

Everything from one source

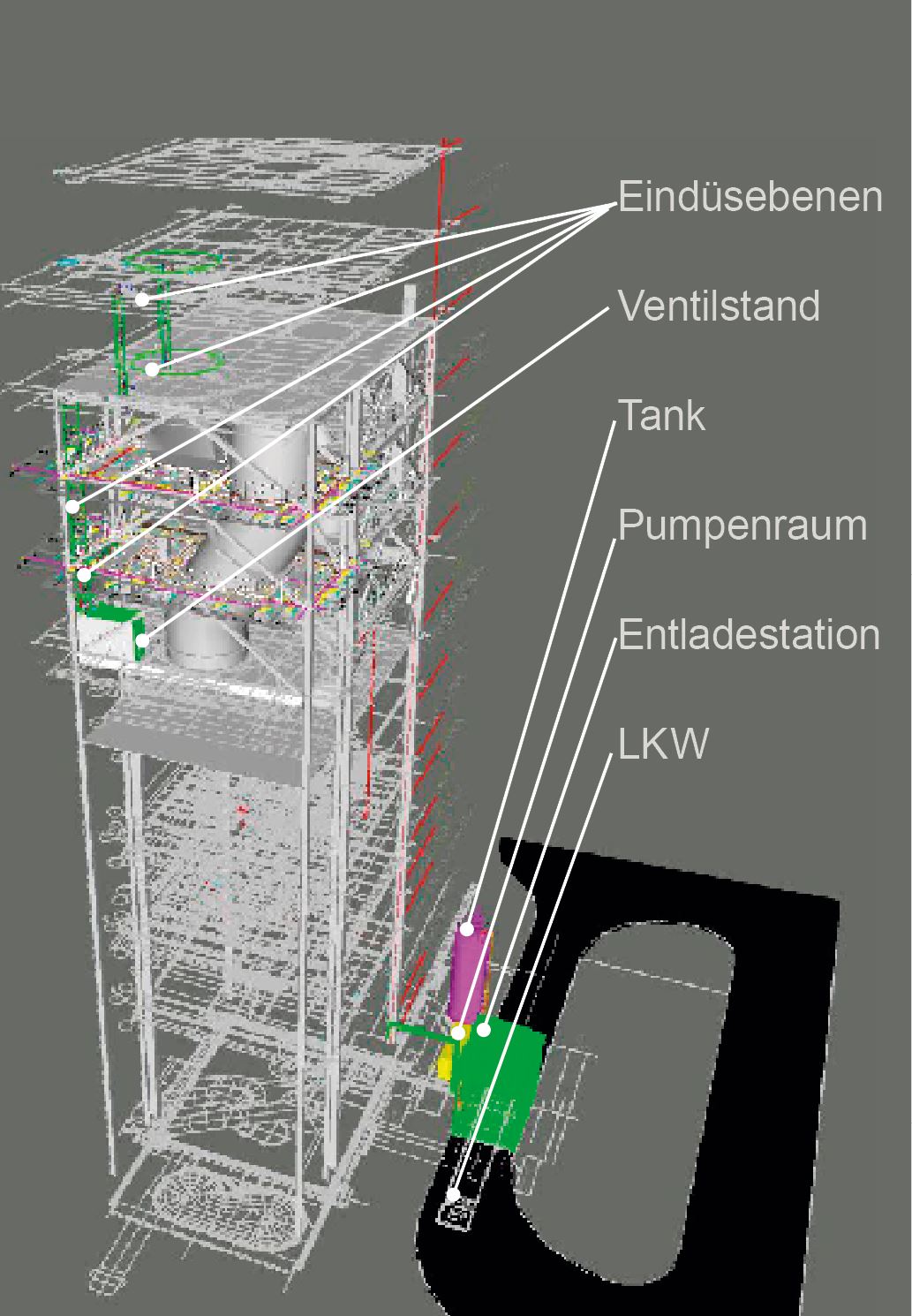

Based on the proven APC control system for SNCR plants developed by VOIGT+WIPP, we integrate complete SNCR plants as turn-key projects with our process engineering know-how. Coordinated components from the pump stand to the nozzle guarantee high availability, best economy and trouble-free, efficient operation.

Together with proven partners, we design the SNCR specifically suited to your existing plant – of course with CE for the total installed power. In addition, we support you with official procedures, plant approval, fire protection and safety.

Together with proven partners, we design the SNCR specifically suited to your existing plant – of course with CE for the total installed power. In addition, we support you with official procedures, plant approval, fire protection and safety.

With the help of our EPOC® Suite, we support you across all trades in the reduction of emissions as well as in the monitoring and automatic diagnosis of your plant by using modern AI methods.

Your benefit

-

Reduction of NOx emissions

-

Comply with current and future limits

-

Minimal use of reducing agents

-

Consumption-optimizing, intelligent control

-

Data online for verification

Your SNCR “Turn-key” in 3 steps

Concept

Compliance with current and future emission limits is essential. The specialists at VOIGT+WIPP Engineers know what is important.

We come and analyze your conditions – existing plant technology, conditions in the furnace, fuel composition, as well as the space conditions at the site – simply all requirements and general conditions to configure the product optimally. Afterwards, the performance limits are precisely fixed in order to avoid surprises later on. This leads to the schedule and pricing for implementation.

The result of the conception phase is a resilient concept for your custom-fit SNCR – clear in terms of technical, economic and scheduling aspects, as a decision-making basis for implementation.

Implementation

From engineering, procurement and delivery to installation and commissioning, VOIGT+WIPP Engineers provides you with everything from a single source. As experienced technology experts, we deliver the complete package around the product core – the AI-based control – together with proven partners as a custom-fit product at a fixed price for you.

Of course, CE for the delivered overall performance picture is just as self-evident as support in approval and testing procedures.

We use extensively tested, proprietary digital technology in the control and connection so that the data on the plant and the operating states are available and visualized in a simple and user-friendly manner.

Overall, we are thus living up to our claim of supplying the SNCR as a turnkey product.

Service

We support your interest in economical operation and lasting value retention of your SNCR system and are available to you as a service partner throughout its service life.

Coordinated with your own capacities, we support you in maintaining optimal operation. This is based on the service and maintenance plan for SNCR, which is included as a performance part. Thanks to the secure digital connection ongoing optimization, adaptation to changing conditions, changes in fuel or plant can be made. Reducing agent consumption is continuously kept at the lowest possible level, and changes are detected at an early stage.

We contribute our extensive know-how on combustion technologies (grate firing, fluidized bed, rotary kiln) and the corresponding process engineering. Your plant remains “state of the art”.

Our Tip:

The APC control of the SNCR with KI is also integrated by us as an integral part in a higher-level plant control (fire power control, production). Our comprehensive basic product for this purpose is the higher-level EPOC® Suite, into which existing controls of the rotary kiln and conveyor system can also be integrated and thus optimized.

Reference projects

Testimonials

“In the course of the upgrading of our fluidized bed boiler by the experts from VOIGT+WIPP Engineers, an SNCR system was also integrated. This not only enables the emission limits to be undercut, it also shows itself to be stable and reliable in operation after more than a year of use. The SNCR control was executed as part of the integrated EPOC suite.”

DI (FH) Bernhard Pichler, Project Manager, NORSKE SKOG