Risk analysis, HAZOP

Carrying out a risk and hazard analysis for operating systems is essential, for example, for issuing a CE certificate or for changes to existing systems (system conversion, renewal of the safety chain). Risks and dangers need to be re-evaluated.

Hazards are identified and evaluated in the analysis. VOIGT+WIPP Engineers use the HAZOP methodology (PAAG procedure), one of the most widely used tools for hazard identification, which is also recognized by the authorities. We use the qualitative risk graph and the LOPA (Layer of Protection Analysis) methodology to assess the risks.

Hazard identification – HAZOP

The HAZOP methodology is used to identify potential hazards and causes of (production) deviations in technical systems. We put together an interdisciplinary team of experts to meet your specific requirements, organize the documents and moderate the analysis meeting. In addition, we also offer to update your as-built documentation.

You benefit from the systematic procedure according to the British Standard (BS IEC 61882), which we follow in carrying out the HAZOP studies. We systematically investigate all deviations from the target state and their consequences. Subsequently, we document the results and derive recommendations for increasing the safety of your processes. We are also happy to support you in implementing these recommendations.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

We are here for you!

Jessica Hübner and Michael Kupa are your experts when it comes to risk analysis

Hazard assessment

The qualitative risk graph

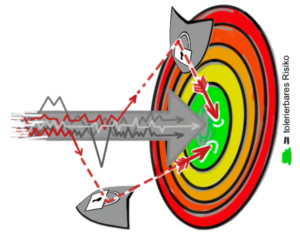

The qualitative risk graph is a widely used method for assessing risks, especially when specific measurements or safety devices are considered. With this methodology, we examine the probability of occurrence of a deviation and its extent of damage, the exposure of people to the hazard, and the preventability of the damaging event.

We then classify all deviations into safety integrity levels (SIL) using a risk graph (based on OVE-EN-61511). These SIL classifications set requirements (failure safety, redundancy) for the entire safety chain and the safety circuits. Each safety function covers the entire route from the measuring sensor to the process control system (the controller) and the actuator. The classification enables you to select the right components and safety devices for your process.

We then classify all deviations into safety integrity levels (SIL) using a risk graph (based on OVE-EN-61511). These SIL classifications set requirements (failure safety, redundancy) for the entire safety chain and the safety circuits. Each safety function covers the entire route from the measuring sensor to the process control system (the controller) and the actuator. The classification enables you to select the right components and safety devices for your process.

LOPA methodology

The LOPA methodology is ideal for assessing risks when only a rough plan or concept is available and basic engineering services are still required. As part of the LOPA methodology, we use a risk matrix to determine the probability of occurrence of deviations and their potential extent of damage.

Subsequently, we compare the risk of the event with the tolerable risk. risk. If the risk of a dangerous deviation from the target state exceeds the tolerable risk, you must take measures. You can either add further safety devices to the process or make improvements that meet a higher safety integrity level (analogous to the Qualitative Risk Graph).

risk. If the risk of a dangerous deviation from the target state exceeds the tolerable risk, you must take measures. You can either add further safety devices to the process or make improvements that meet a higher safety integrity level (analogous to the Qualitative Risk Graph).

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

Further information: