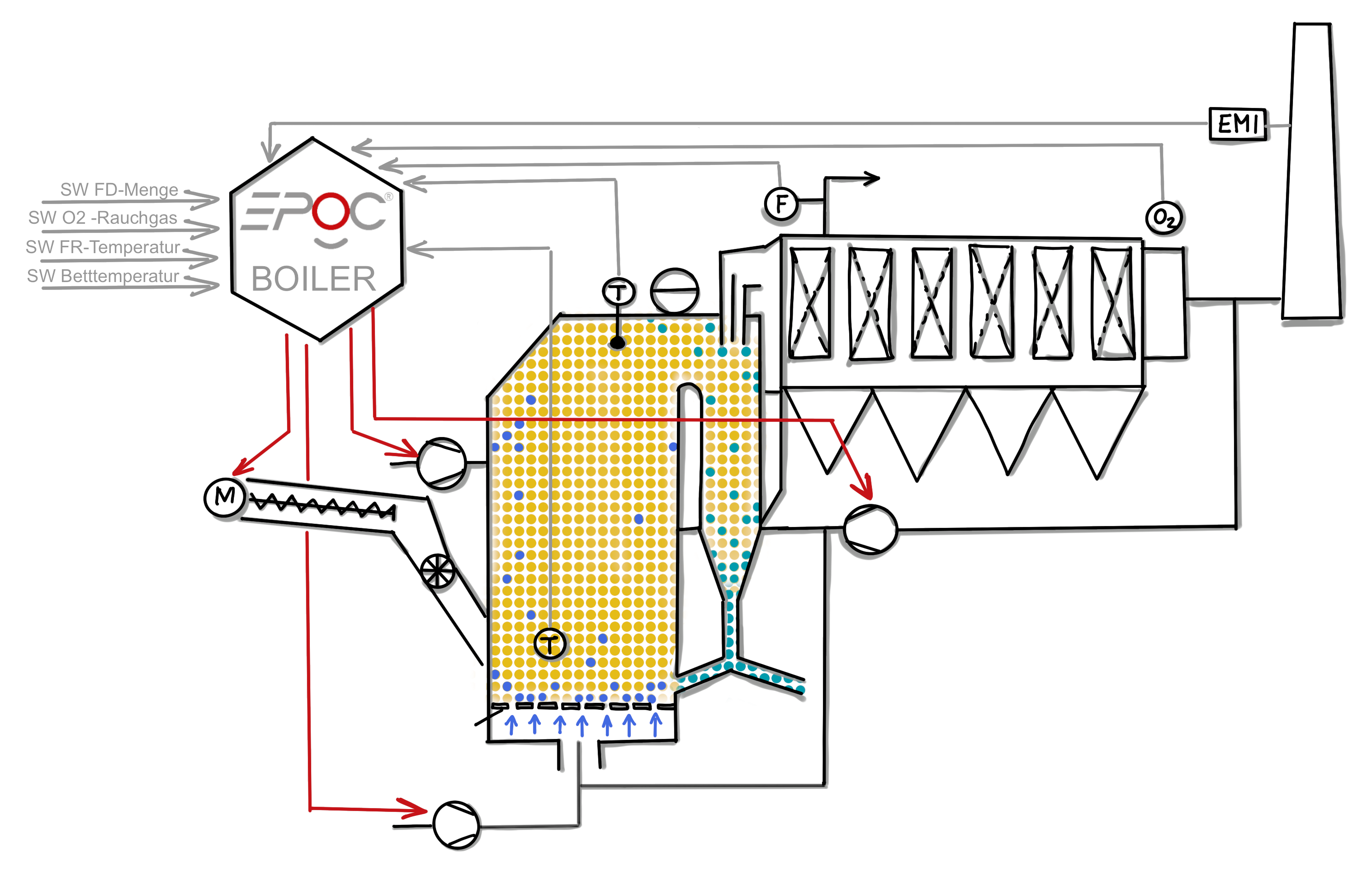

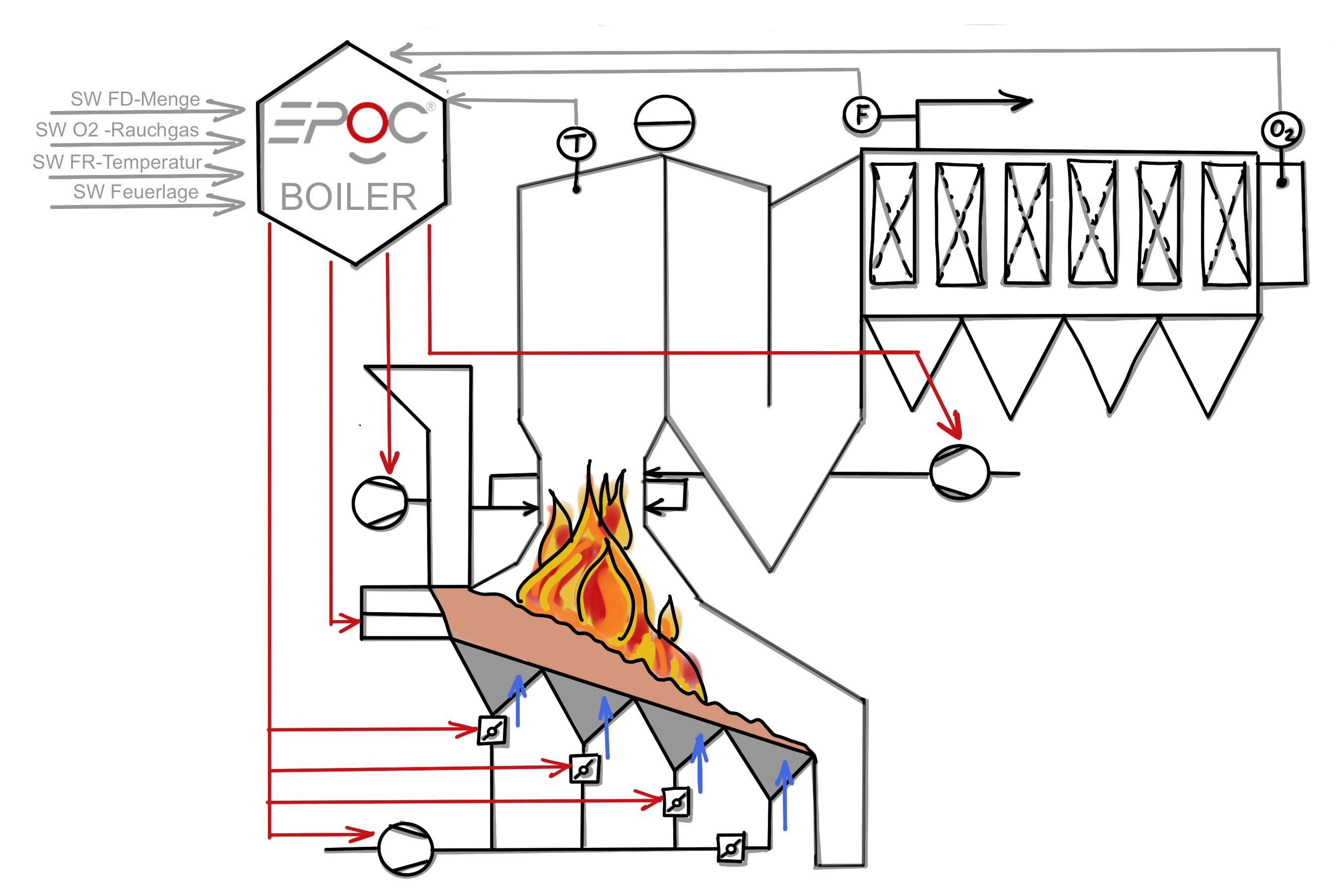

EPOC® Boiler

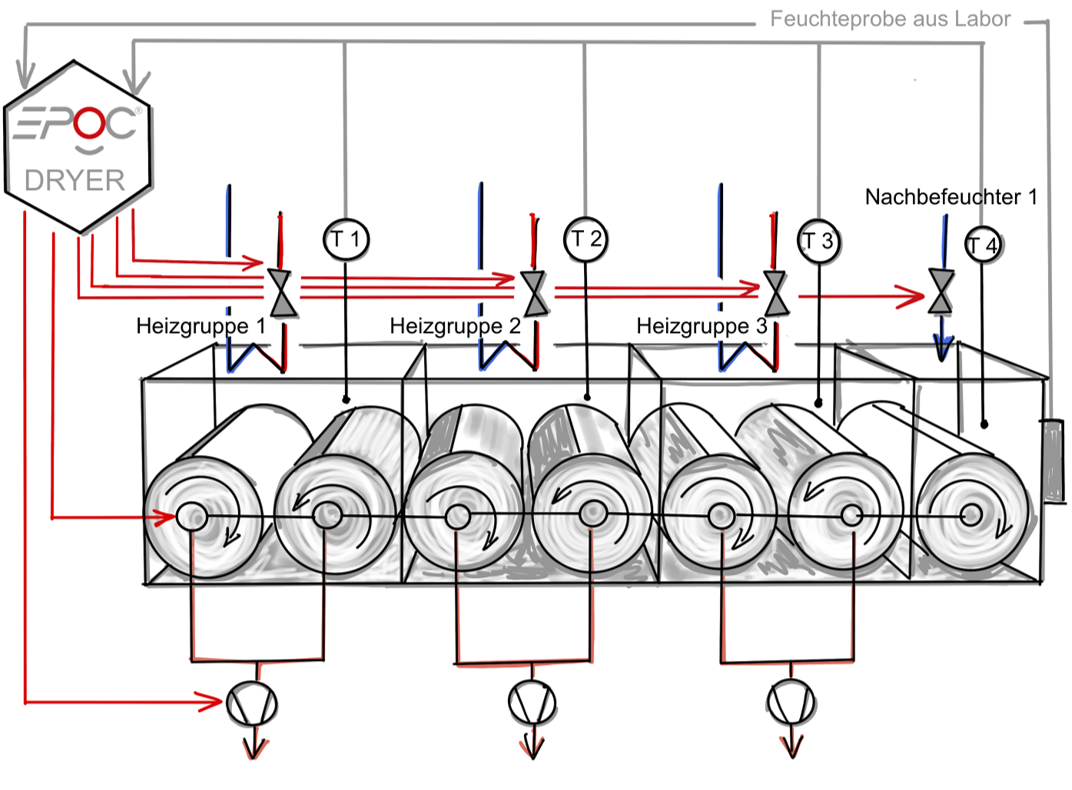

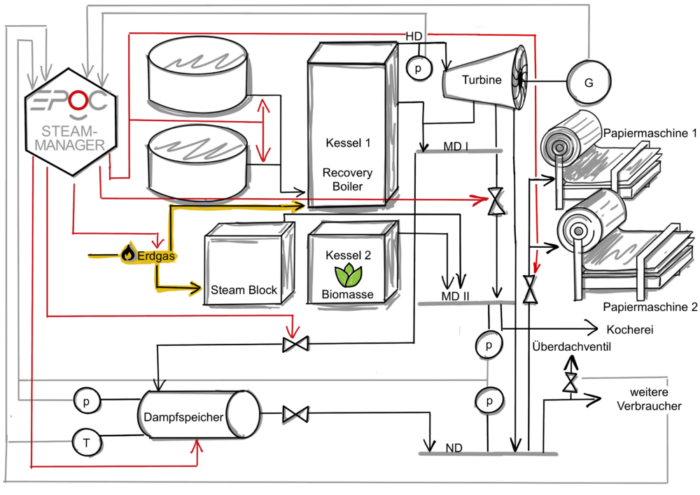

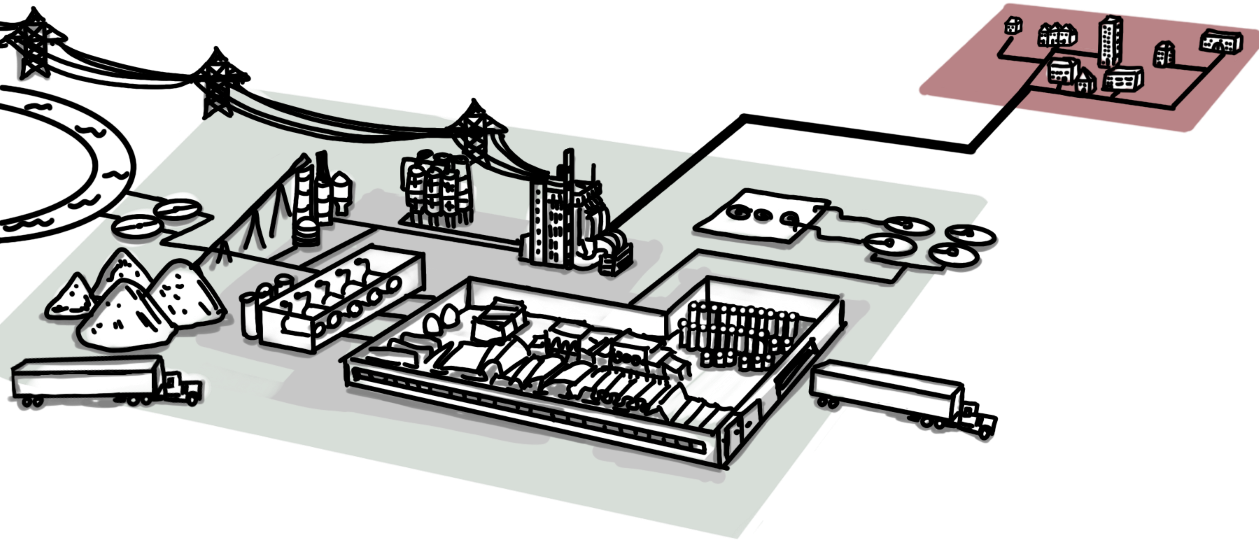

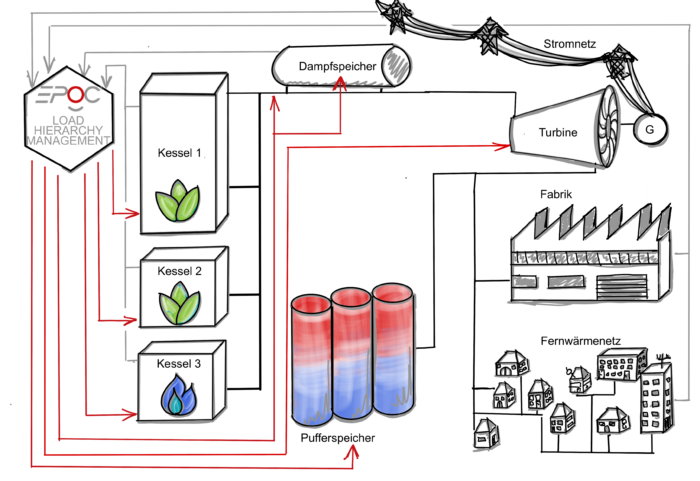

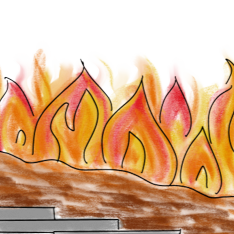

EPOC® Boiler is the firing rate control for all common boiler designs and includes grate firing systems, fluidized bed boilers or rotary kilns. EPOC® Boiler is optimized for different fuels: Biomass, waste wood, wood dust, caustic and residual / waste. In particular, the challenge of heterogeneity and variability in fuel is optimally managed.

The control system ensures stable and uniform combustion with optimum burnout behavior for the respective defined load cases. All relevant manipulated variables are taken into account to ensure optimum fuel use. The focus is on asset-friendly operation with long travel times as well as compliance with emission limits.

You benefit from a consistent, performance- and efficiency-optimised firing system. The constant combustion conditions and low boiler fouling extend the travel time of your plant with lower annual maintenance costs. EPOC® Boiler also increases the degree of automation of your system and thus reduces the necessary manual interventions by your employees. Thanks to the increased energy efficiency and reduced emissions, you make an important contribution to climate protection. Of course, EPOC® Boiler does not affect your existing safety functions in any way.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Sebastian Sturm is your expert when it comes to the EPOC® Suite!

Further links:

During implementation, comprehensive data analyses and physical-dynamic process simulations are carried out to optimise the control concept that is ultimately used. Implementation is possible in a turnaround time of three to five months and can take place during ongoing operations. Safety-related functions are not affected.

-

Improved burnout

-

Stable combustion edge

-

Increased heat yield

-

Increased boiler efficiency

-

Increase in maximum boiler output

-

Stabilisation of combustion and residual oxygen content

-

Compliance with all control parameters

-

Stabilisation of fan operation

-

More uniform ember bed at all load levels

-

Intuitive operation

-

Reduction of own power consumption (electricity costs)

-

Reduction of malfunctions and manual interventions

-

Avoidance of unburnt residues

-

Reduction in fuel consumption or increase in waste throughput

-

Reduction of the operating times of the peak-load boiler and the back-up firing requirement

-

Higher electricity production

-

Reduction of flue gas losses

-

Extended plant travel time

-

Constant compliance with emission limits

-

Reduction of emissions (CO, CO peaks…)

-

Increased energy efficiency, improved efficiency

-

Reduction of fossil fuel demand (peak load boiler – oil/gas)

-

Contribution to sustainability reporting