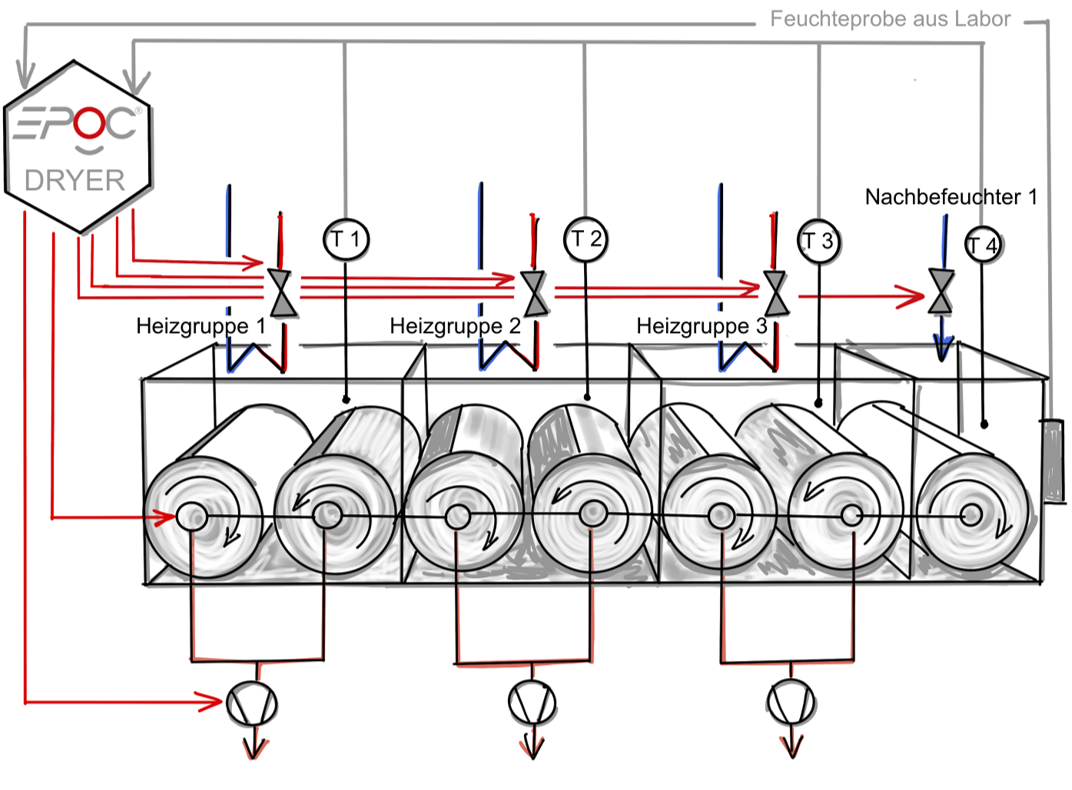

EPOC® Dryer

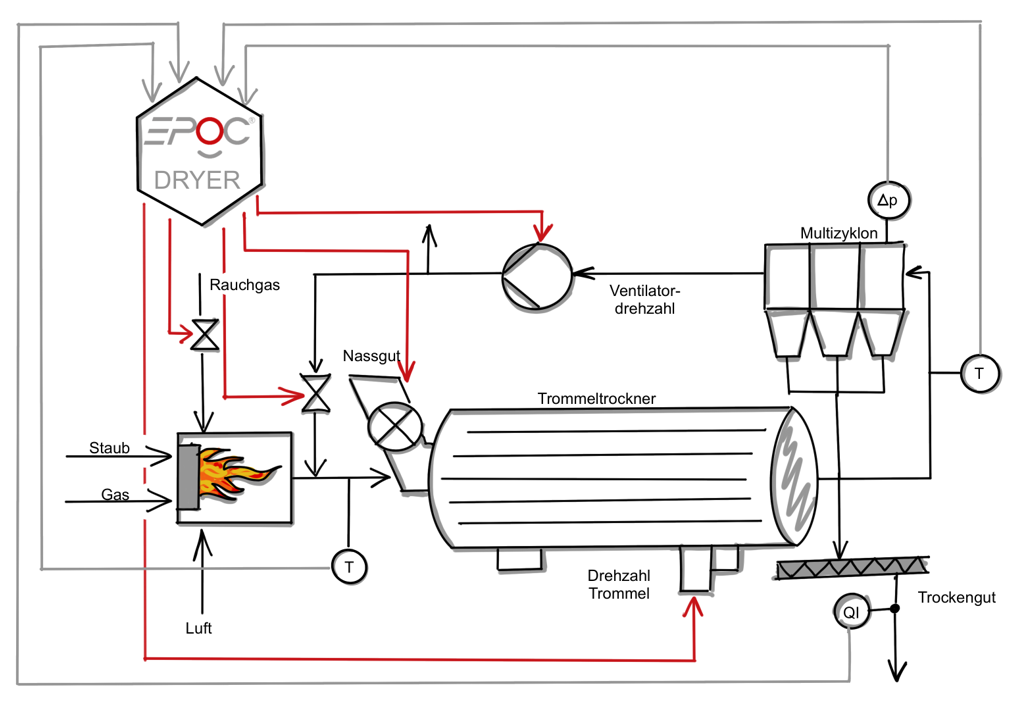

The EPOC® Dryer regulates process temperatures and product quality proactively with the given control variables. This includes the control of the heat source with the objectives of creating optimal combustion conditions for low-emission operation and ensuring an optimal drying process with smooth balancing of heat demand and heat availability.

With the EPOC® Dryer, you improve the energy efficiency of your system, save fuel, reduce the CO₂ footprint of your product, comply with emission limits and make a substantial contribution to continuous product quality thanks to uniformity (residual moisture).

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Sebastian Sturm is your expert when it comes to the EPOC® Suite!

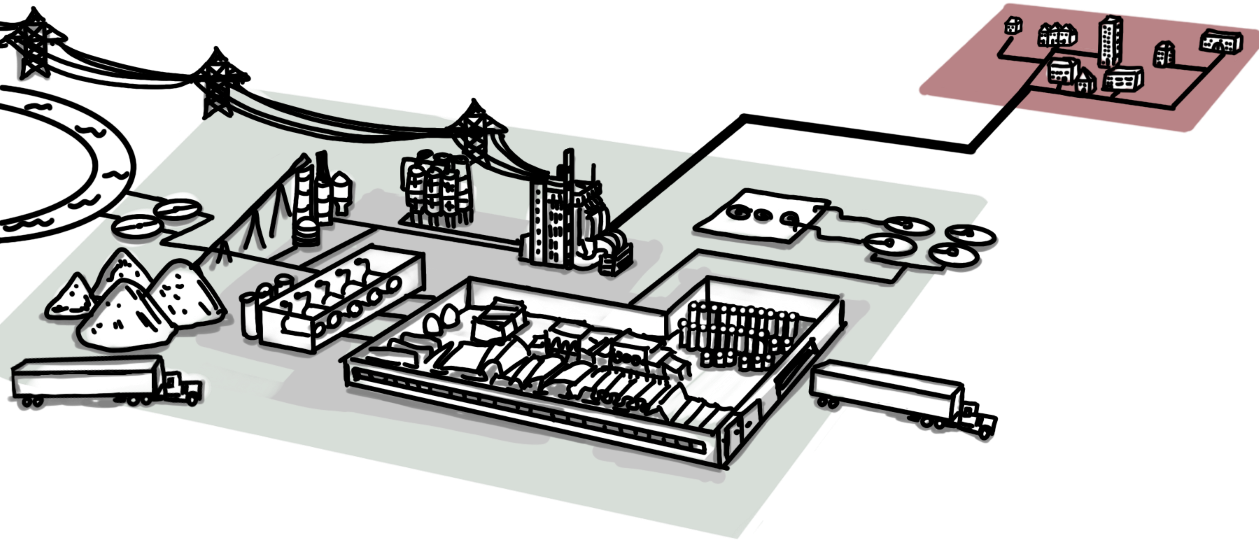

In several industries (pulp industry – pulp dryer, paper industry: paper machine, wood-based materials industry – chip dryer, impregnation channels, wood industry, food industry) drying or dewatering represents an essential process step.

With the focus on emission reduction and the environmental goals following the EU taxonomy, the energy-intensive drying process is increasingly becoming the centre of attention. We have the corresponding process know-how in the industries mentioned. The experience from many implemented projects is already anchored in the pre-configured EPOC Dryer.

Different dryer designs are taken into account – drum dryers, belt dryers, entrained-flow dryers. We are thus in a position to quickly record the respective situation based on data and to put the EPOC Dryer into operation in compact implementations with short processing times.

-

High control performance of the drying plants – high product quality

-

Minimum fluctuation range during operation

-

Ongoing improvement of control strategies

-

Easy operation, optimal training and thus better performance

-

Dynamic compensation of raw material changes

-

High degree of automation, minimal operator intervention

-

Short commissioning times – cost and time savings

-

High operating performance

-

Homogeneity of dry material moisture

-

Flexibility in the properties of the dry material

-

Variable throughput thanks to integration of higher-level functions

-

Optimum energy efficiency thanks to optimum process control

-

Reduction of specific energy consumption

Do you have any questions? Should we call you or would you prefer to be informed by e-mail?