Engineering

At VOIGT+WIPP Engineers, we have been leaders in process and control engineering plant optimization for many years. For the benefit of numerous customers from industry and energy supply, we combine several specialist disciplines to make the most of existing systems in terms of comprehensive sustainability – economically, ecologically and technically.

When optimizing and upgrading systems, it is often necessary to adapt existing systems and provide comprehensive services from engineering to implementation. Our experienced team of technologists and engineers is ready to understand your individual requirements and develop customized solutions.

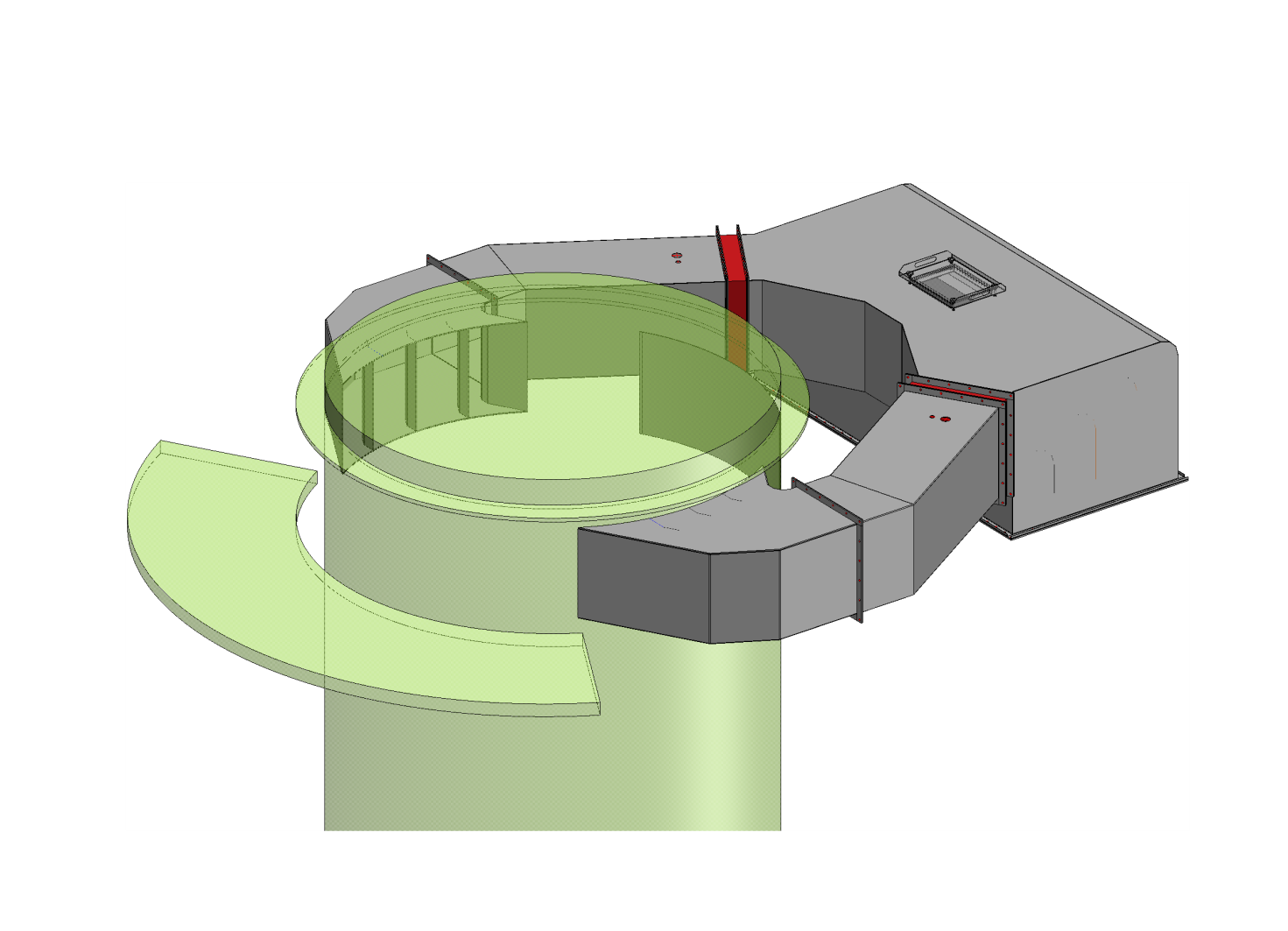

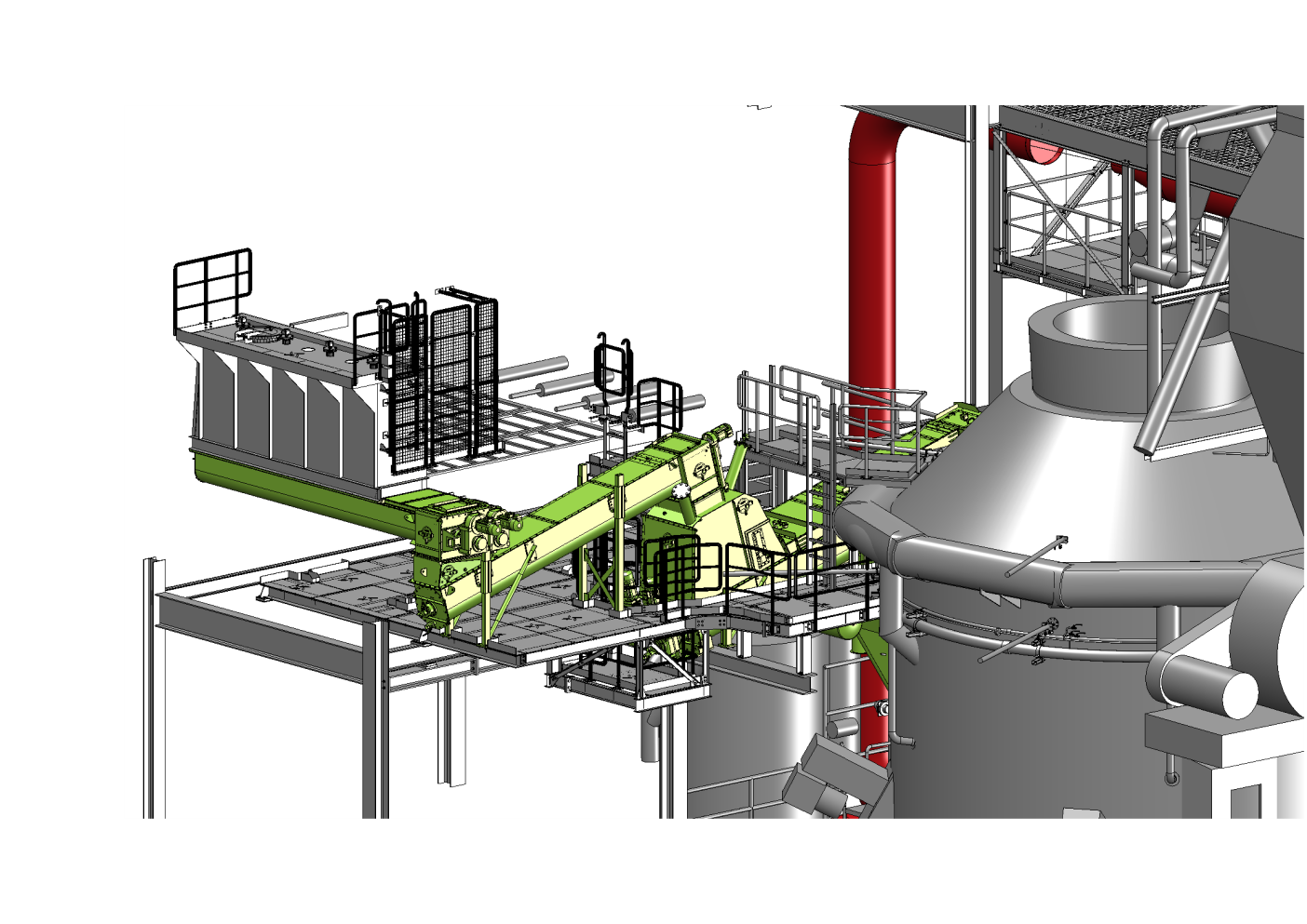

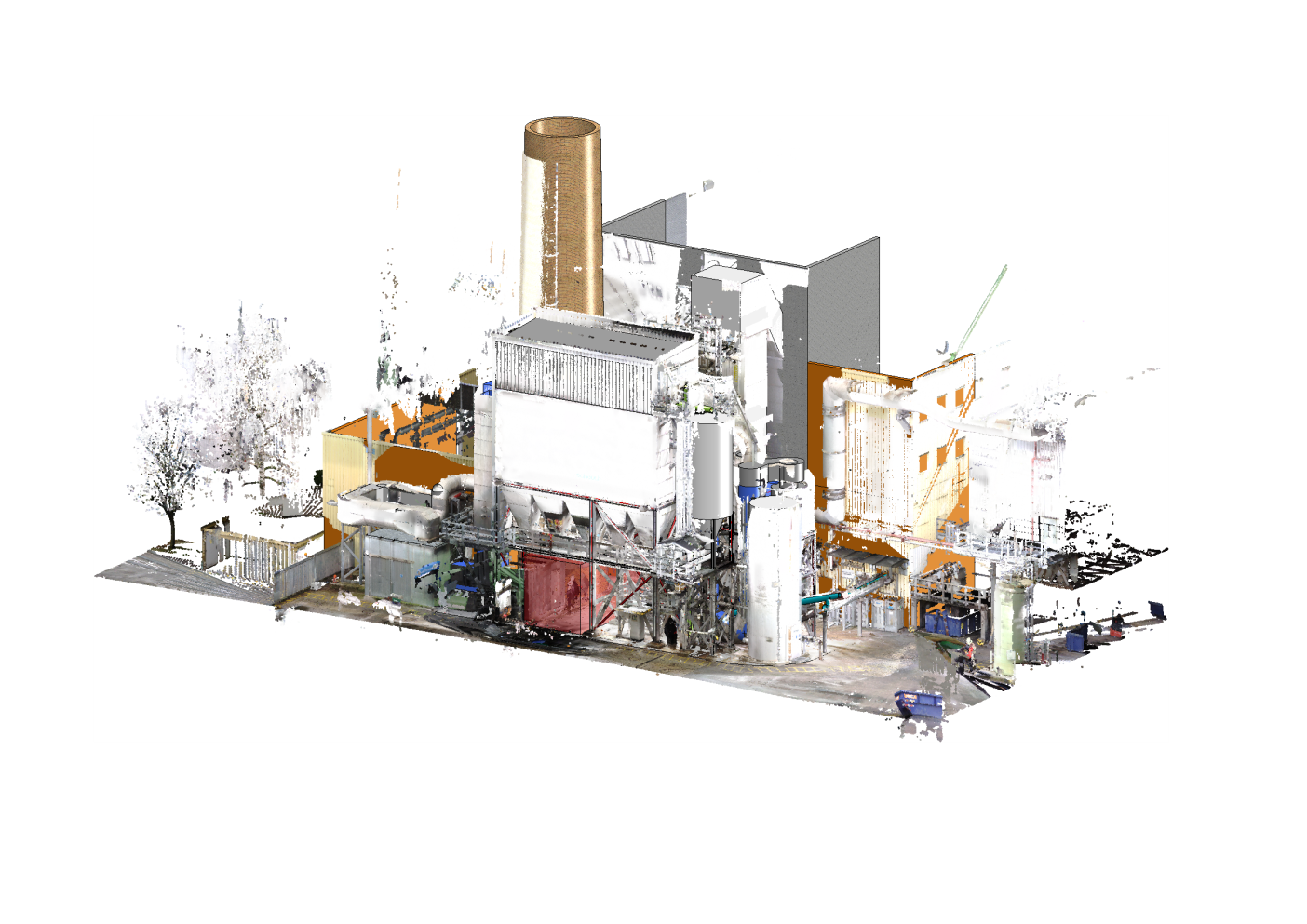

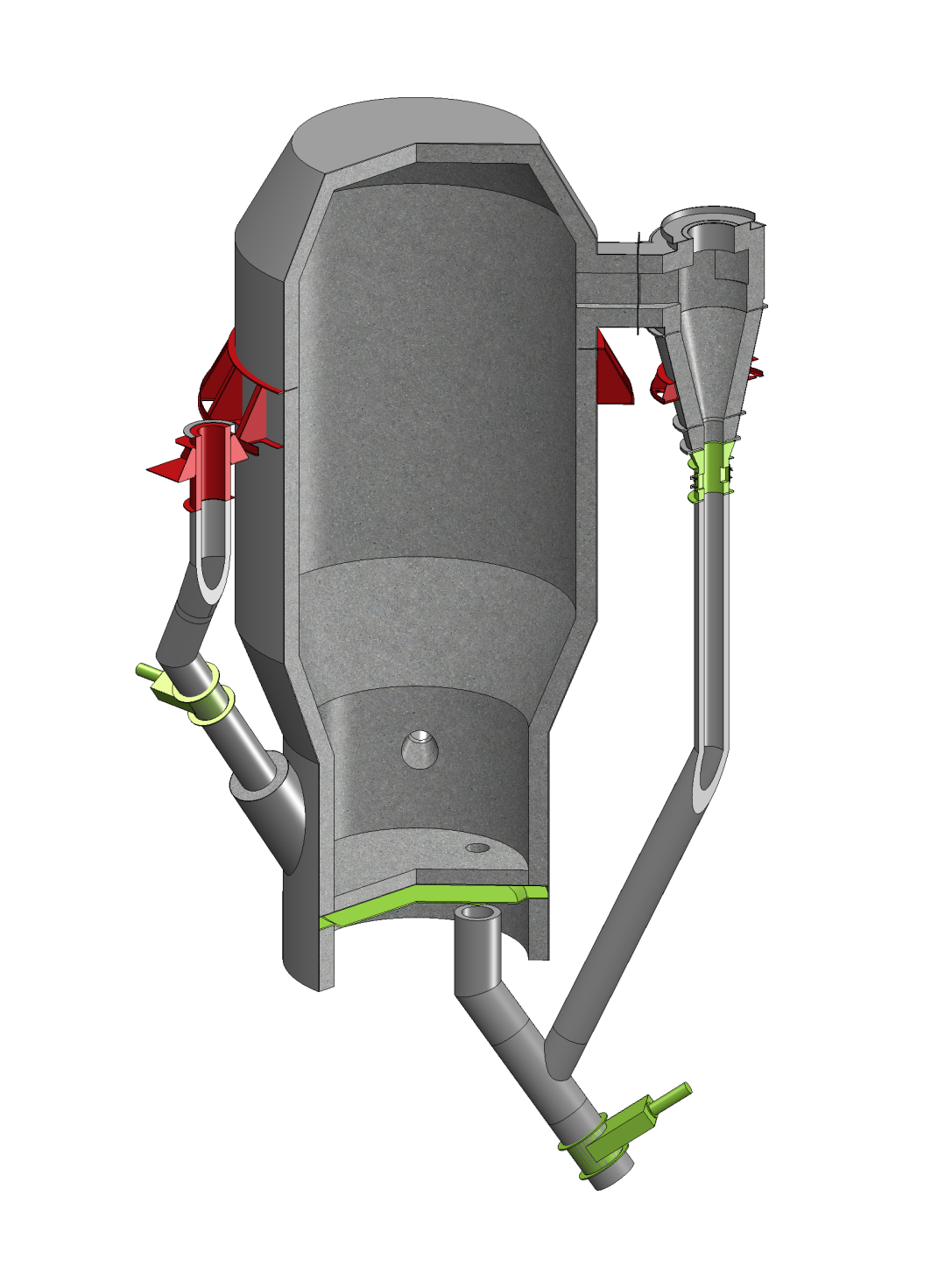

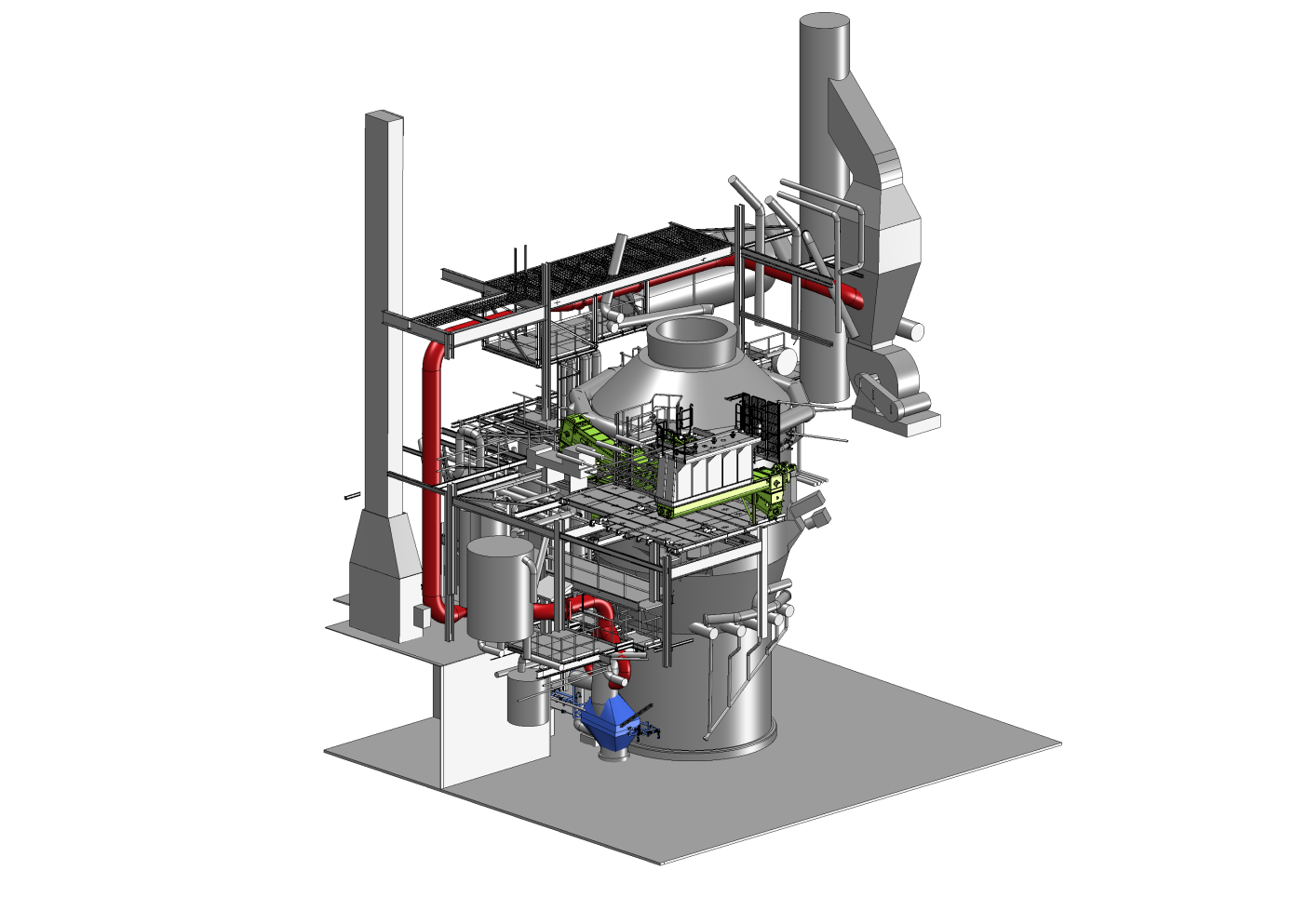

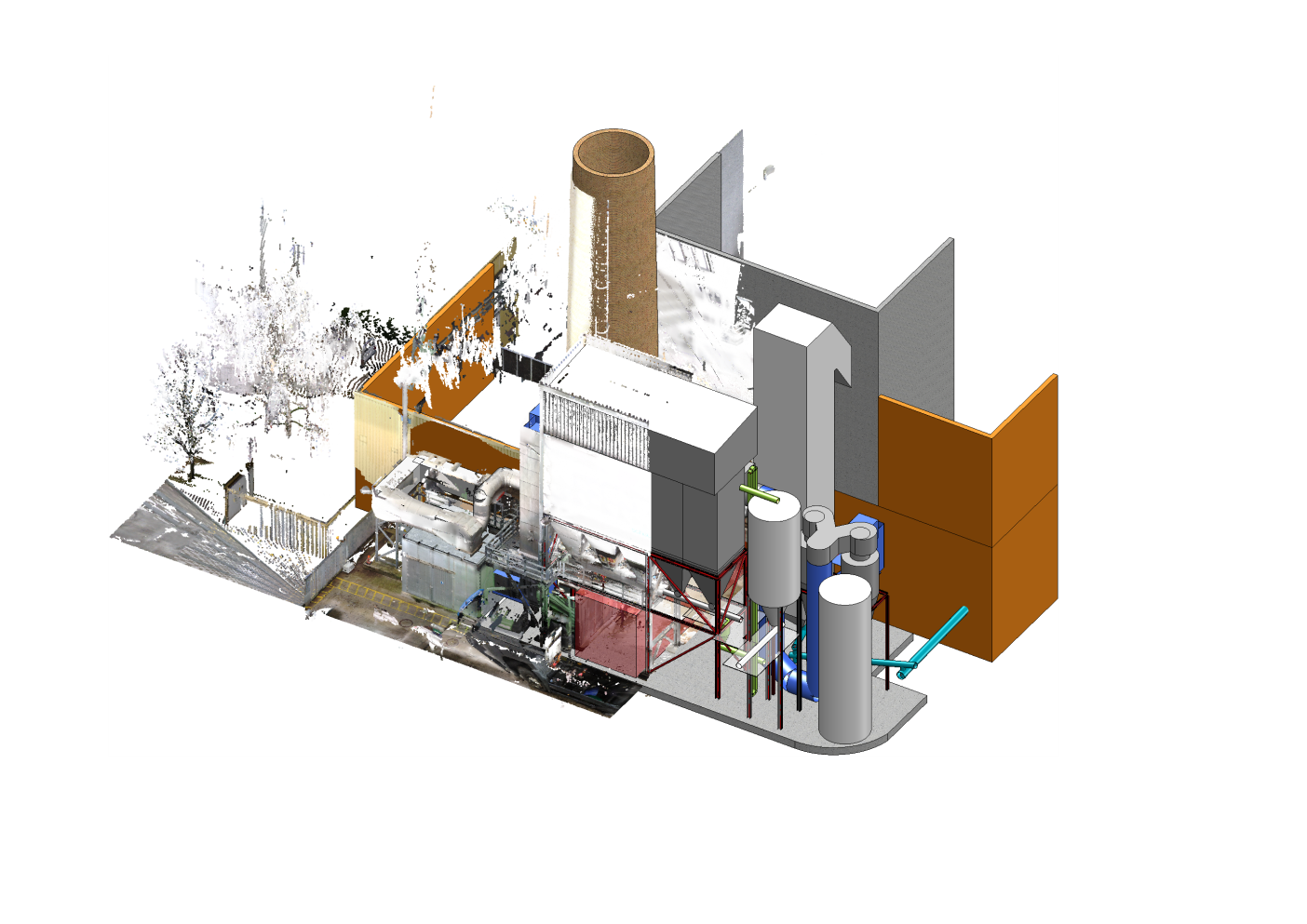

The examples are many and varied: the fuel supply in existing buildings needs to be adapted and automated to make dosing much more precise: We record the stock, for which there are often no current digital models, in a 3D scan, design the adaptation or redesign, coordinate this technologically and have 3D models at an early stage in order to involve everyone involved. Depending on the customer’s requirements, this concept engineering can be handed over to our own technical departments or the adaptation can be continued as a complete package from basic to detail engineering.

Of course, we accompany the engineering in the respective level of detail, starting with cost estimates through to suitably precise CAPEX and OPEX calculations, thus supporting investment decisions

t

I am happy to be there for you!

Dominik Gappmaier is your expert when it comes to engineering and 3D modeling !

The key phases in plant engineering

In plant construction, projects always go through several engineering phases, which are similar regardless of whether it is a new flue gas cleaning system, a conversion of the recirculation air or the retrofitting of a flue gas condensation system.

The fundamentals are outlined in concept or pre-basic engineering, developed in basic engineering and precisely specified in detail engineering.

Concept or Pre-Basic Engineering

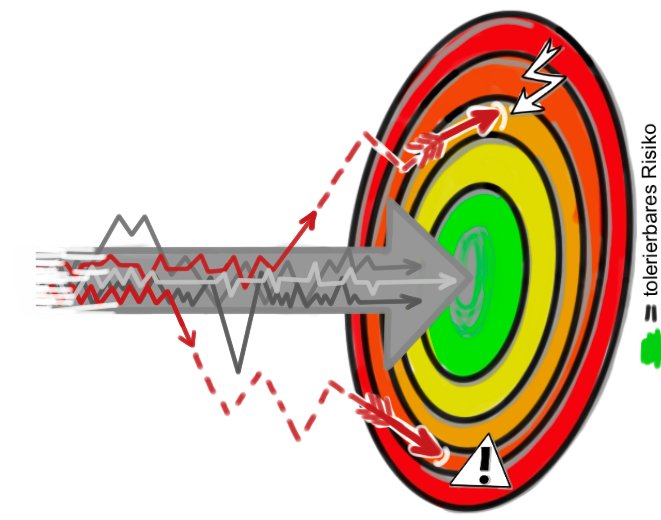

In the initial engineering phase, the customer’s requirements and wishes usually need to be recorded and analyzed and checked for feasibility. Feasibility always involves a combination of technology, systems engineering, cost, requirements and implementation lead time.

The requirement is challenging: decision-makers want to see a clear basis for a decision on the desired solution as a sketch with as little effort as possible, have the effort limited and have a good preview of the effect – quite simply: a basis for a decision.

Basic Engineering

Now the existing concept from the previous phase needs to be concretized, loads and dimensions need to be calculated precisely, the main requirements also need to be narrowed down further and design specifications also need to be made regarding components such as pumps, tanks, heat exchangers, sensors and actuators

The 3D model visualizes, for example, the embedding, the layout and all relevant characteristics of the system or system conversion. Costs (CAPEX) and benefits (OPEX, ecology, emissions, etc.) are further specified. The risk and safety considerations are integrated in the appropriate depth.

Detail Engineering

The concepts and specifications from basic engineering are reviewed and refined in detail engineering, which is often also carried out by contractors as part of the execution service. The system components are finally dimensioned and detailed. 3D modeling and design play an important role here to ensure precise and efficient planning for everyone involved.

Detail engineering is the solid basis for production and assembly and therefore for implementation.

An important final part of detail engineering is the “As Built” planning, which is ideally handed over in digital form.