Project implementation

Services in procurement and awarding

As early as the basic engineering stage, the first consultations are usually held with competent suppliers, authorities and testing bodies regarding components that require approval. Procurement and awarding of contracts are therefore heavily dependent on the results of the basic and detail engineering.

In the detailed engineering phase, the details (functionality, process-related advantages and disadvantages, etc.) are worked out with the pre-coordinated manufacturers and then the best overall service partner is selected for the respective application. Here it is essential to have a well-developed project plan drawn up in advance and to keep a precise eye on the overall performance picture. Furthermore, practice has shown that this project plan enables us to react quickly and competently to unforeseen situations, thus keeping your costs to a minimum.

As early as the procurement phase, we take into account the implementation period agreed with you, so that the delivery of the components can be ideally controlled in conjunction with the installation.

Services for delivery, assembly

Following the procurement phase, the ideal time for delivery and installation is selected for you as the client. For necessary downtimes, we use revision time windows to reduce interruptions to the plant to a minimum. Good planning of space availability on site, especially when parallel investments are being made, is a basic prerequisite for successful implementation.

The basis for successful assembly implementation is always sound assembly planning with the contractors. This also includes the planning of space availability on site, which is of great importance especially in the case of parallel conversions. We can draw on extensive experience and adapt quickly to specific requirements and rapidly changing circumstances. With our competent, carefully selected partners, we also carry out complex assembly work within the shortest time windows.

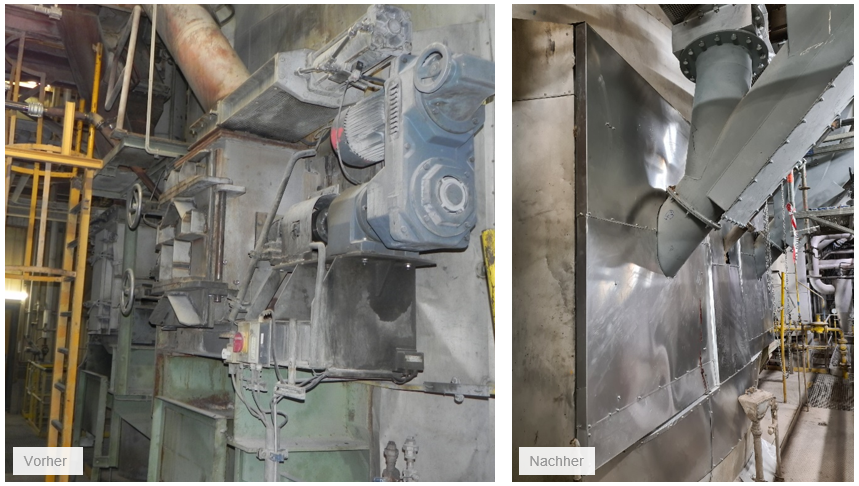

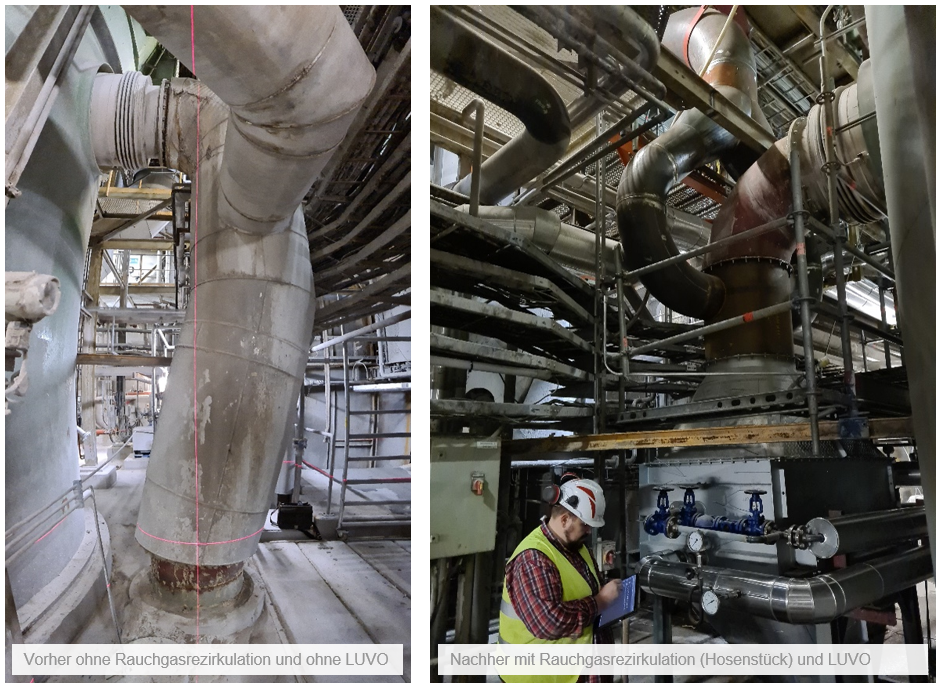

The year 2020 in particular was very complex in terms of delivery reliability. Nevertheless, it was precisely here that we were able to bring our strengths to bear and complete an extensive modernisation and optimisation project of a fluidised bed furnace from 1984 on time.

Even if the best technical solution is a complex one, we implement it with great care and competence.

Commissioning and optimisation services

Commissioning and optimisation after completion of all mechanical work is the last important step to ensure the planned benefits.

We carry out the commissioning of the services/works involved together with the respective manufacturers, document the process and hand over after successful implementation. We ensure a clear transition of services and the certainty that this will only take place with planned functionality. Professional commissioning planning, the supervision of commissioning (of the performers) and the performance of acceptance tests by our process and control engineers are common steps here.

Further optimisation begins immediately after commissioning. Our know-how combination of control engineering, process engineering and digitalisation enables unique expertise for the successful commissioning and optimisation of complex overall conversions.

The concrete agreement of the acceptance process with the service partners already begins with corresponding definitions in the procurement phase and builds on the concepts from design and implementation planning.

Warranty

Our warranty is usually up to two years after handover of the system. It goes without saying that our systems are always CE-compliant.

At your request, we will also be happy to issue an overall CE for our scope of services. This ensures that your system can be fully approved by the authorities after our completion.

Related topics

Products

Blog article on the topic