BCS® fire power control

BCS® fire power control

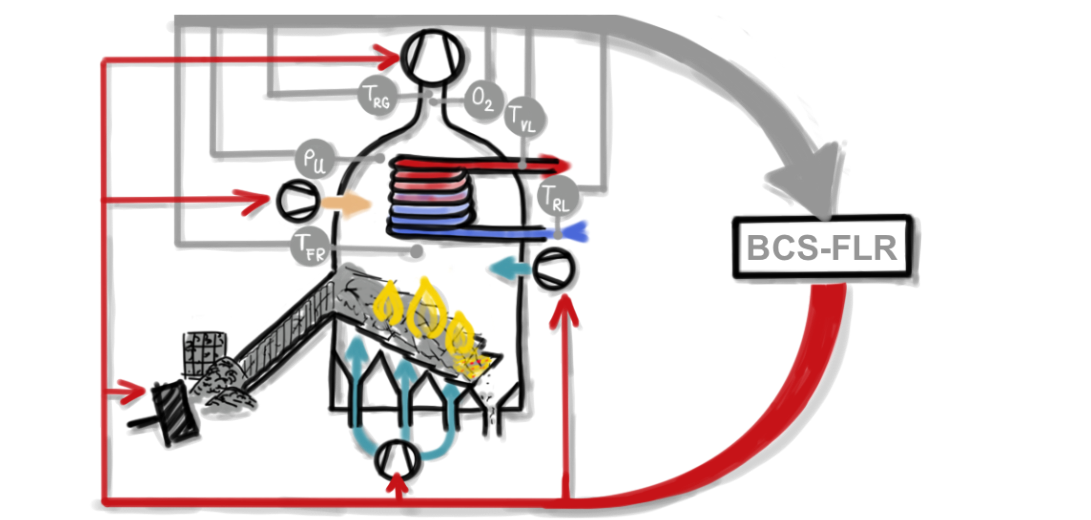

The BCS® fire output control ensures optimum, complete combustion and boiler efficiency. The decisive factor here is the perfectly harmonized coordination of the fuel feed, the grate movement as well as the supply of combustion air and recirculated flue gas.

Building on a stable fuel bed in the combustion chamber, we achieve a calming of the aggregates and measured values with our control system. Vibrations are reduced, resulting in a higher average output while maintaining the same limits. This stable driving mode enables operation without exceeding the limit values.

This means that little or no manual intervention is necessary during normal operation. You benefit from greater fuel flexibility and an overarching increase in efficiency. You can also expect higher output with the same material input. The problem-free handling of changing fuel quality increases flexibility in fuel purchasing.

This means that little or no manual intervention is necessary during normal operation. You benefit from greater fuel flexibility and an overarching increase in efficiency. You can also expect higher output with the same material input. The problem-free handling of changing fuel quality increases flexibility in fuel purchasing.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

David Hechinger is our expert for your BCS® Suite!

BCS® firing power control: Your advantages at a glance

-

Improved burnout

-

Stable burnout edge due to active fire position control

-

Increased heat yield

-

Increased boiler efficiency, increase in maximum boiler output

-

Stabilisation of combustion and residual oxygen content

-

Stable compliance with all control variables

-

Stabilisation of fan operation

-

More uniform burnout edge at all load levels

-

Intuitive operation

-

Reduction of own power consumption (electricity costs)

-

Reduction of malfunctions and necessary manual interventions (reduction of personnel costs)

-

Avoidance of unburnt residues in the ash (disposal costs)

-

Reduction of fuel use (fuel costs)

-

Reduction of peak load boiler operating times (fuel costs)

-

Higher electricity production

-

Reduction of flue gas losses

-

Extended plant travel time

-

Constant compliance with emission limits

-

Reduction of emissions (CO, NOx, NH3, …)

-

Increased energy efficiency

-

Reduction of fossil fuel requirements (peak load boiler – oil/gas)

-

Contribution to sustainability reporting