BCS® steam extraction control

BCS® swath removal system

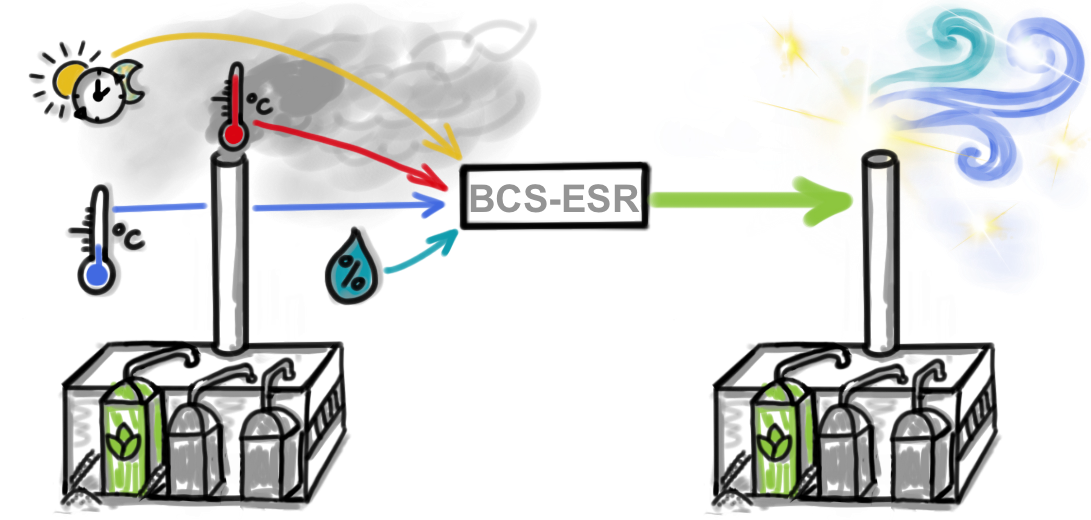

The BCS® steam extraction control (ESR) prevents the formation of steam in the chimney of biomass boilers with flue gas condensation systems. By calculating the minimum amount of fresh air required, the power demand is significantly reduced and the condensation of the water vapour contained in the flue gas on the chimney is effectively prevented. The switch-off and switch-on times as well as the temperature window for the de-vaporisation operation can be freely selected.

To prevent the formation of water vapor (“windrow”) at the chimney, the flue gas from the biomass combustion is mixed with preheated fresh air. The deaeration control calculates the minimum amount of deaeration air that must be added to effectively deaerate the flue gas.

For this purpose, the maximum relative humidity of the mixing line between flue gas at the stack and the ambient air is calculated and regulated to a setpoint by means of a deaeration air damper. A setpoint value below 90% results in a steam-free flue gas. In order to protect the air preheater from frost damage, the de-swathing can be deactivated from a certain temperature. This prevents the flue gas from cooling too much at the “cold end” of the air preheater, which would lead to icing of the heat exchanger.

Advantages of the BCS® swath removal systemAdvantages of the BCS® swath removal system

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

David Hechinger is our expert for your BCS® Suite!