Potential study – the ideal start for your optimization project

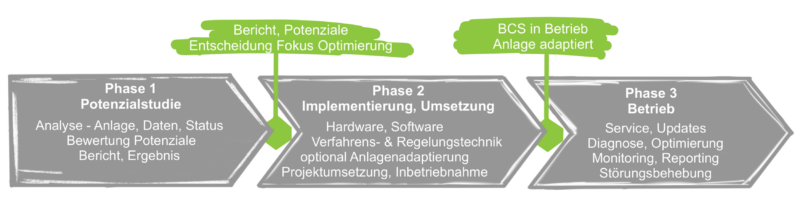

A potential study by VOIGT+WIPP Engineers meets several requirements. On the one hand, we summarize the identified potential in a clearly structured manner based on a well-founded analysis of the respective systems on site and the available data. In addition, we derive sensible and practicable measures that affect both control technology and process engineering.

The value of a potential study therefore lies in the appealing and helpful presentation of data and facts, in the analysis in which process and regulatory expertise and experience are combined, and in concrete concepts and proposals for implementation.

The overarching goal: to improve the effectiveness and efficiency of existing systems, minimize environmental impact and exploit their full potential with as little effort as possible.

Our approach to potential studies:

The first step is to clarify the objective, classify the appropriate analysis steps and estimate the effort involved.

Once the order has been placed, an initial analysis is carried out based on the available documentation and process data for the systems.

During an on-site visit (usually lasting several days), issues that have already been identified are examined in greater depth and the plant is inspected and analyzed in terms of process technology.

Depending on the depth of the analysis, the size of the system and the in-depth question, the firing system is simulated in parallel (for example with IPSE Pro) or the buffer storage tank, heat transfers or the heating network / steam network are also examined in depth.

The potential derived from the combination of system analysis, data analysis, simulation and experience is specifically identified, evaluated (qualitatively, quantitatively) and presented.

As the final part of the elaboration, possible/useful steps for utilizing the potential identified are derived and condensed into a meaningful proposal in coordination with any projects that may already exist on the customer side.

Diverse potential

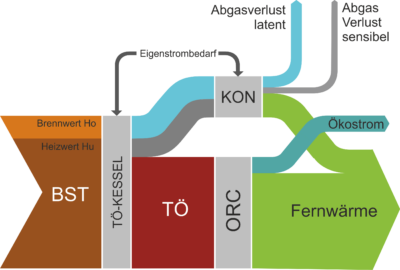

Energy potential is usually found where losses occur. The most obvious are storage losses (fuel), losses in the furnace (e.g. due to unburned fuel), flue gas losses, losses due to unstable operation or grid losses.

In many cases, systems have already been optimized by the operators, which means that further improvement by leveraging new potential appears uneconomical at first glance. The in-depth data analysis with highly developed tools and the consideration of the latest best practices enable an objective view.

Less obvious potentials are often of a dynamic nature. Some examples of this are

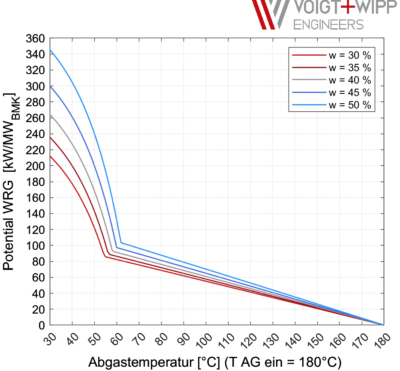

Heat recovery potential from the flue gas in kW per MW boiler output for different fuel water contents and flue gas outlet temperatures, boiler flue gas temperature: 175 °C

- Optimized interaction between energy system, heat storage and consumer

- Maximizing performance and improving the handling of different fuel qualities

- Reduction in system losses and electricity consumption

- Increase in (eco-)power decoupling through stable driving style

In any case, a holistic, overarching concept that includes not only individual system components but also the entire system with its control technology interaction is crucial for sustainable exploitation of potential.

The result and the success factors

The result is a study summarized in the form of a report, which is presented, discussed and debated with the customer’s experts.

The result is a study summarized in the form of a report, which is presented, discussed and debated with the customer’s experts.

Clarity, traceability and trust are key success factors when conducting potential studies and subsequently using them for optimization work.

In order to ensure the necessary common understanding of the system, good communication, intensive exchange and clear, comprehensible documentation of the process engineering relationships and possibilities are important in the study development.

Plant safety is of the utmost importance in our analyses. Our work therefore involves identifying safety risks and proposing measures to improve plant safety. This helps to ensure safe and reliable operation.

Identified potentials and their evaluation are professionally derived by our engineers, underpinned with balance sheets or simulations and presented in a comprehensible manner using graphical representations.

The actual, substantial benefit naturally arises from the implementation of the proposed measures. Accordingly, we also see the potential study as the first step towards subsequent implementation.

Conclusion of potential study: No system too small – hardly any too large

The total amount of energy generated annually is the key factor influencing the cost-effectiveness of measures to increase energy efficiency. For large energy systems, even small improvements quickly become economically viable.

Because smaller energy systems are neither comparable in terms of technology (sensors, actuators, automation, control, process data, etc.) nor with the human resources of larger systems, optimization potential is often neither identified nor exploited. As a result, smaller systems have greater potential in percentage terms, which in turn enables optimization projects to be implemented economically. (Especially for smaller systems: Find out more about our BCS fit product here)

The experts’ view can thus lead to valuable insights for all system sizes.