Controller technologies used

Model Predictive Control – MPC

Model predictive control uses a mathematical model of the controlled process to optimally control the controlled variable. For this purpose, the model is continuously compared with the real process variables and used to predict the future behaviour of the process.

We further use this prediction in a real-time optimisation to find the optimal manipulated variable for the current time step. As a result, very fast, stable control of your process is possible, through which we achieve significant improvements (e.g. compared to PID-based concepts).

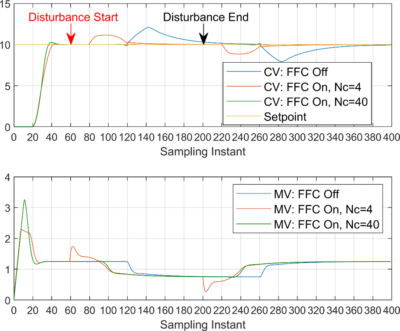

By taking known disturbances into account in the target function, it is possible to compensate for disturbances with very long dead times without critical controlled variable deviation by means of appropriate feedforward control (FFC).

By taking known disturbances into account in the target function, it is possible to compensate for disturbances with very long dead times without critical controlled variable deviation by means of appropriate feedforward control (FFC).

The use of MPC offers significant advantages in the control of non-linear systems. These include, among others, the implicit treatment of manipulated variable constraints as well as the possibility to optimally operate systems very close to these constraints, the simple extension to multivariable systems as well as the model-based consideration of system dead times.

Especially the control of the latter system class represents a typical application of model predictive control structures.

Your advantages of MPC control at a glance

- Control of multi-measurement systems (MIMO) with an MPC

- Integrate disturbances model, minimise control error

- Consideration of non-linearities

- Reacting to known future setpoint changes

- Direct compensation of dead times

- Direct consideration of static/dynamic constraints

- Optimise the process at each time step

- Accelerate transient process changes

- Minimise losses due to setpoint changes

- Enable stability verification

Neural Networks

In contrast to classical models, neural networks represent numerous non-linear functions and thus represent complex and multi-dimensional problems.

Any number of complex non-linear effects can be represented, with the major limitation that many process data must be available and the model is only valid for plant states present in these process data (no extrapolability).

Neural networks independently extract relevant correlations from large amounts of data. This makes them a valuable addition to physical-logical modelling, which is often insufficient or only feasible with a great deal of effort.

In practice, we use neural networks as so-called black-box models.

We address the following problems with neural networks

- Non-linear system identification

- State observer design

- Controller design

- Neural adaptive control

- Neural optimal control

- Reinforcement learning

- NLq stability theory

Fuzzy Control

In order to achieve optimal control performance and generate long-term added value, we also incorporate concepts from the field of fuzzy control in the sense of holistic APC solutions into the respective specific customer solutions, depending on the problem and objective.

PID Loop

PID controllers are the most versatile type of controller. We adapt the controller behaviour to your specific application through a variety of practical approaches:

- Intelligent min/max limits

- Situational freezing of the controller output

- Feedforward control

- Gain scheduling for different controller dynamics

- Anti-windup for cascade controls

- Limiting controllers that are switched through to the controller output by a min/max selection

- Controller tracking when the controller is inactive for skip-free switching

Related topics

- Advanced Process Control

- Firing rate control

- Dryer systems

- Waste incineration plants

- Industrial wastewater treatment plants

Products

Blog article on the topic