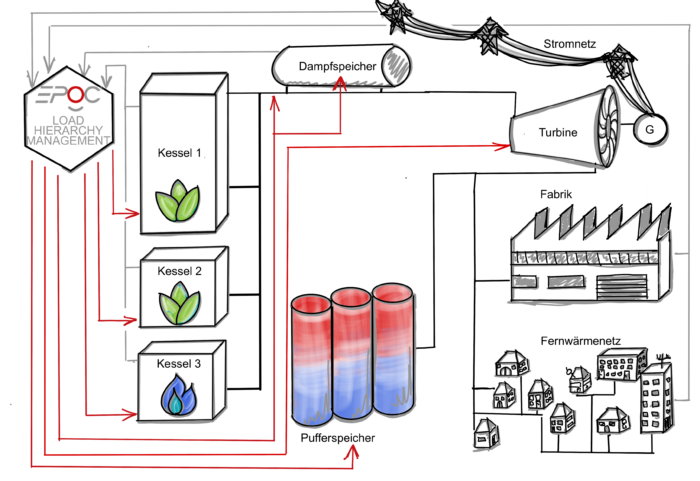

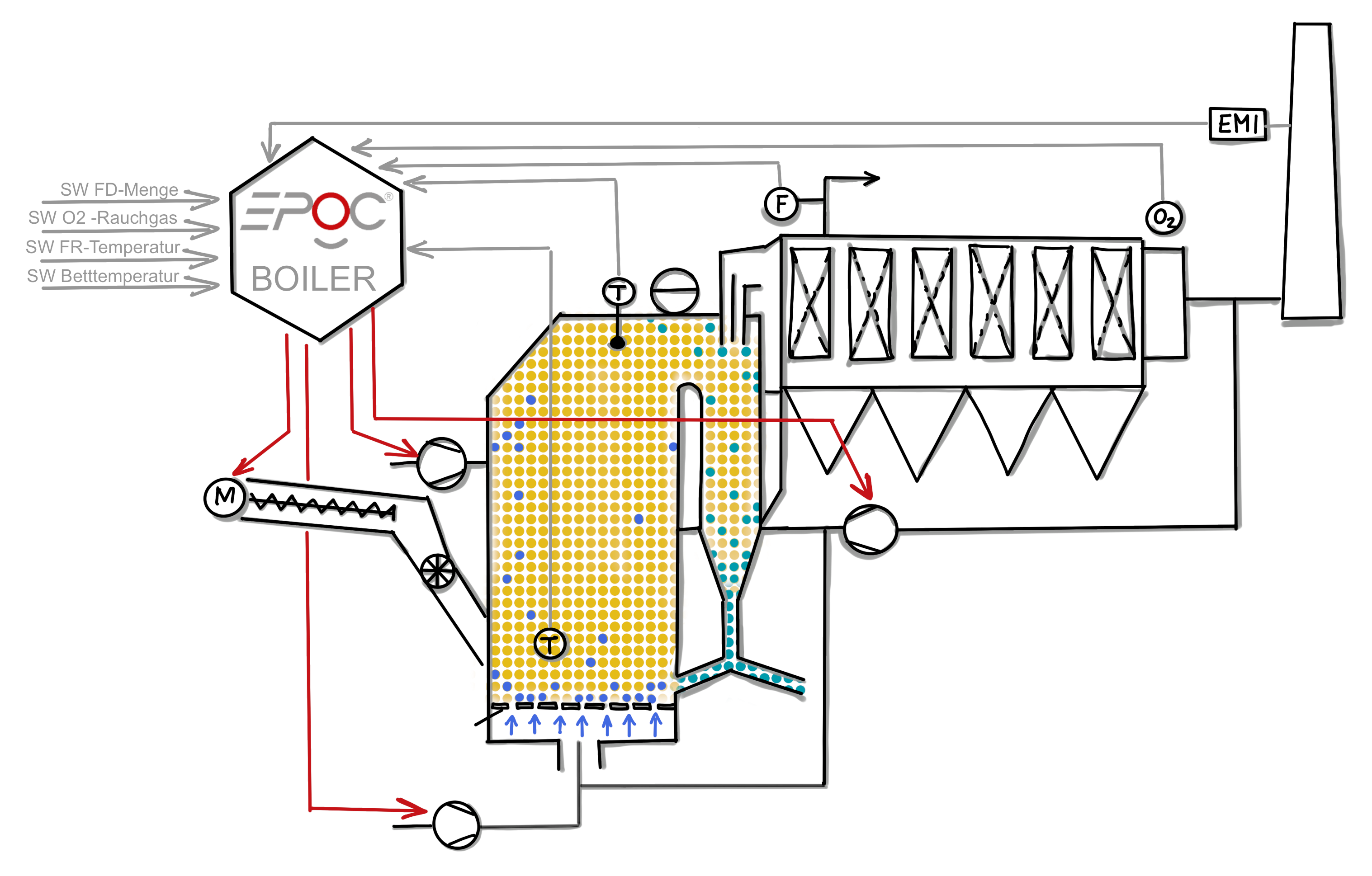

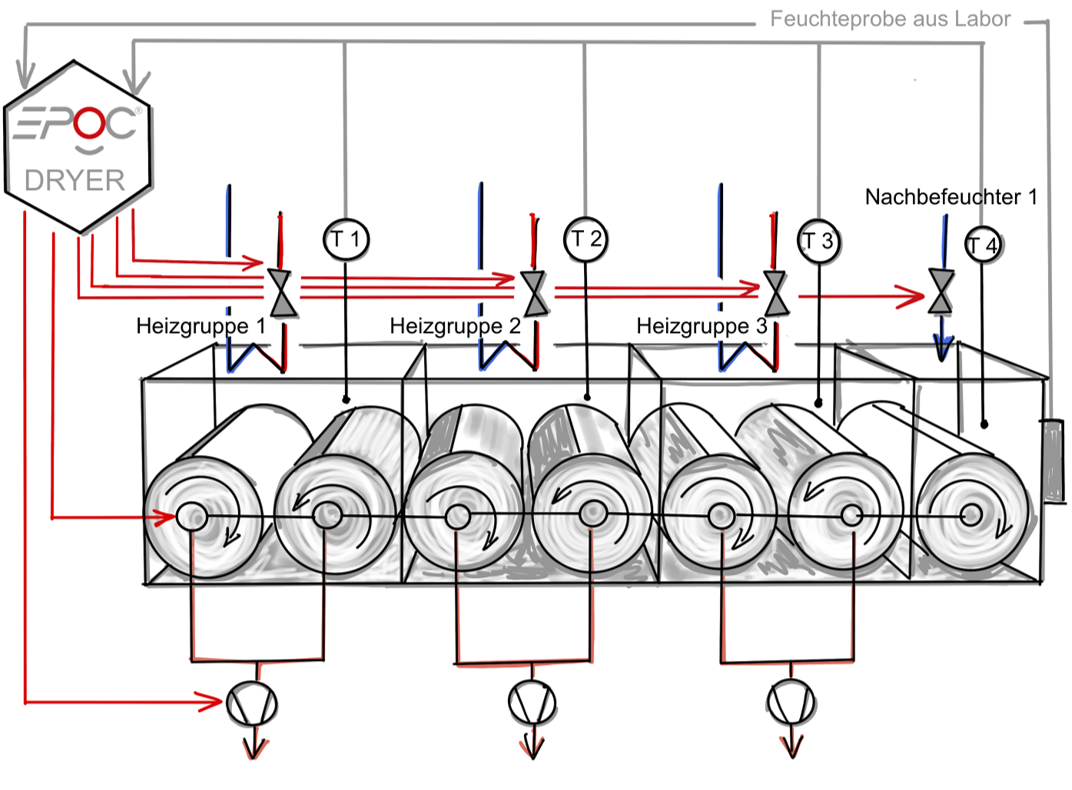

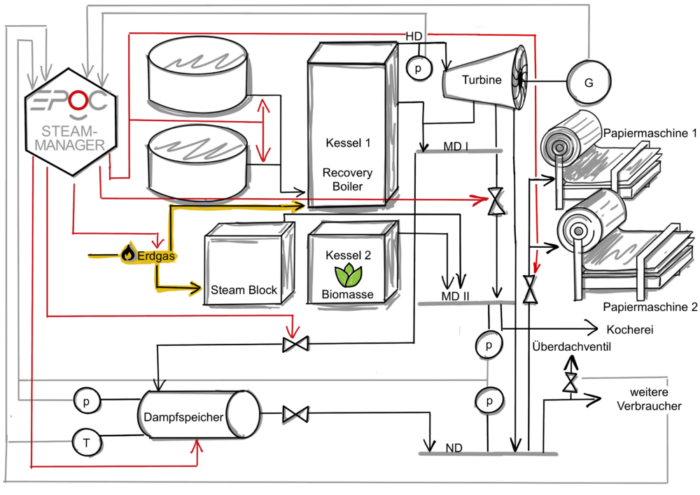

EPOC® Load Hierarchy Management

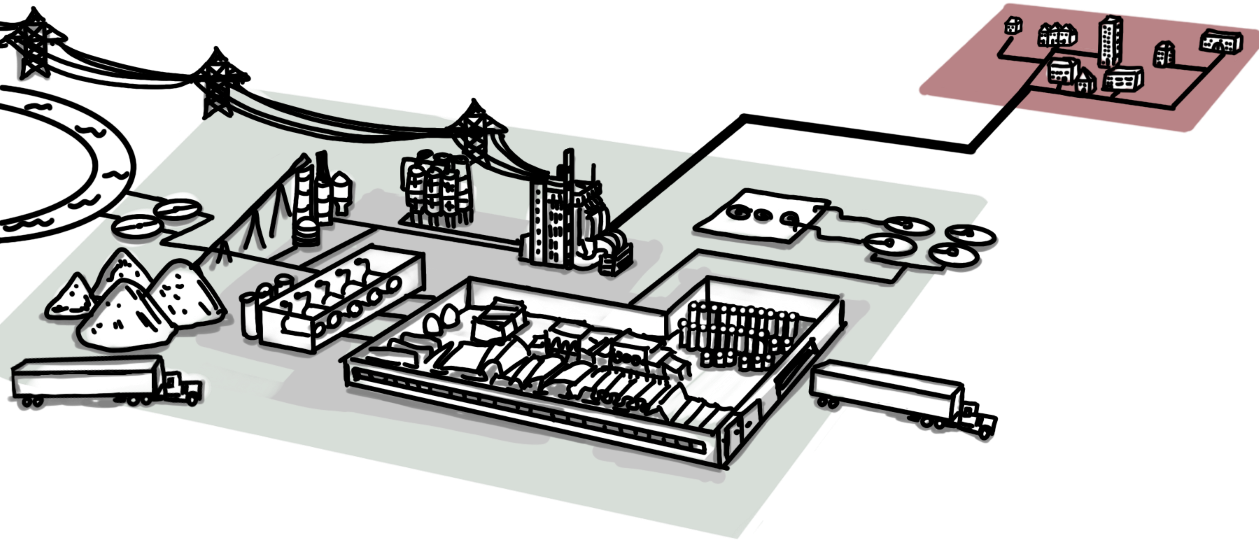

In some plants, two or more boiler lines are operated in parallel. These boilers feed into the same high-pressure steam line. Parallel operation often leads to “swinging up” of the boilers and in extreme cases even to their failure. Traditionally, this problem is solved by a guide boiler. However, this results in efficiency losses because the other boiler(s) are not fully utilized. In contrast to the classic solution, EPOC® Load Hierarchy Management calculates all load setpoints in a superordinate manner so that boiler efficiencies are maximized.

In addition, the load setpoints react much faster to steam disturbances in a coordinated manner. EPOC® Load Hierarchy Management allows you to save fuel while maintaining performance, thus reducing your costs. Your plant achieves its optimal overall efficiency by optimising the energy use of different energy sources and by using energy buffers in your system. You also reduce the emission of greenhouse gases.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Sebastian Sturm is your expert when it comes to the EPOC® Suite!

The integration of the control of the peak load boilers ensures the optimal feeding of one or more peak load boilers. The feed-in times can be defined precisely, depending on the plant and supply criteria. In the event that several peak load boilers are available, their sequence during activation is also controlled. In addition, a “soft” feed is implemented to prevent the displacement of biogenic heat generators.

-

Optimal use of prioritized boilers / energy sources (e.g. following the gas price or CO₂ footprint)

-

Preventing displacement of prioritized energy sources.

-

Optimal use of the given buffers / reservoirs

-

Reduction of malfunctions and necessary manual interventions

-

Reduction of the fuel input

-

Reduction of the operating times of the peak load boiler

-

Optimum yield – electricity / heat

-

Constant compliance with emission limits

-

Reduction of emissions

-

Increased energy efficiency

-

Reduction in the need for fossil fuels – thus reduction in CO₂

We will be happy to send you further information without obligations on your side. You decide whether you would prefer us to contact you by e-mail or telephone. Let’s talk!