CO2 reduction/avoidance concept

With the publication of the EU taxonomy (Regulation 2020/852) in June 2020, the changes in CO2 pricing/taxation and the rising costs of CO2, the demands for effective concepts for CO2 reduction or CO2avoidance are rapidly increasing.

We combine the fundamental objectives for climate protection anchored in the EU taxonomy with the long-standing objectives of companies regarding optimisation, reduction of fuel use or also reduction of emissions.

The focus is on energy-intensive industry and its corresponding requirements and economic levers.

The condensed motive for CO2 reduction: rising CO2 costs

The assumptions underlying economic calculations about the cost forecast for CO2 emissions until 2040 are rough and are based on the following aspects:

- The current average forecast of international analysts for the price per tonne of CO2 in the EU ETS is around 50 – 70 EUR in 2021. An expansion of certificate trading to areas that are currently not obligated is likely.

- More than 12 EU states already have a direct or indirect CO2 tax, partly via fuel and greenhouse levies, partly via direct taxes. Austria will follow suit in 2022.

- The level of these levies is currently 13 EUR/t (Spain), 25 EUR/t (Germany), 40 EUR/t (France), 42 EUR/t (Norway) 55 EUR/t (Finland), 80 EUR/t (Switzerland) and currently a maximum of 100 EUR/t (Sweden).

- In addition to the actual levies to be expected, there will be incentives or subsidies for a switch (reward system).

On the basis of these aspects, a virtual CO2 price of 150 EUR/tCO2 in 2030 – however designed – can be assumed.

In the first approach, concepts and their implementation concern the improvement of existing plants. This is done either by process engineering adaptations (e.g. fuel changes) and optimizations or by control engineering optimizations. Here we design solutions for CO2 reduction “from coal to biomass” or also “from gas to biomass”.

Example: from gas2biomass

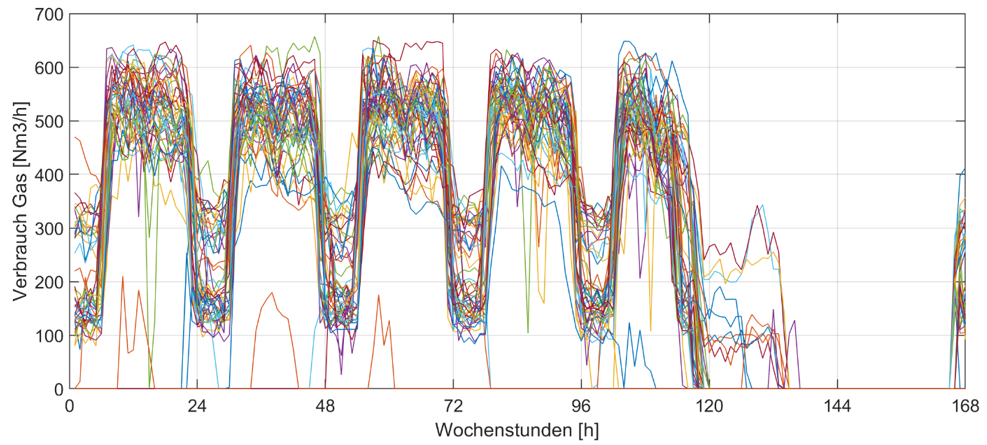

This example shows the task of optionally converting a gas-based steam production for an industrial manufacturing process (multi-shift operation with breaks at weekends) to biomass. The performance curve of the weeks shows the challenge of the weekends. In a well-founded analysis, the concept is implemented on the basis of actual data.

Consumption curves are aggregated from actual data available over the period of a year on the daily gas demand of the plant and then analysed. This analysis of the performance curves of all operating weeks illustrates the daily changes in performance between the day and night shifts as well as the challenge of the weekends.

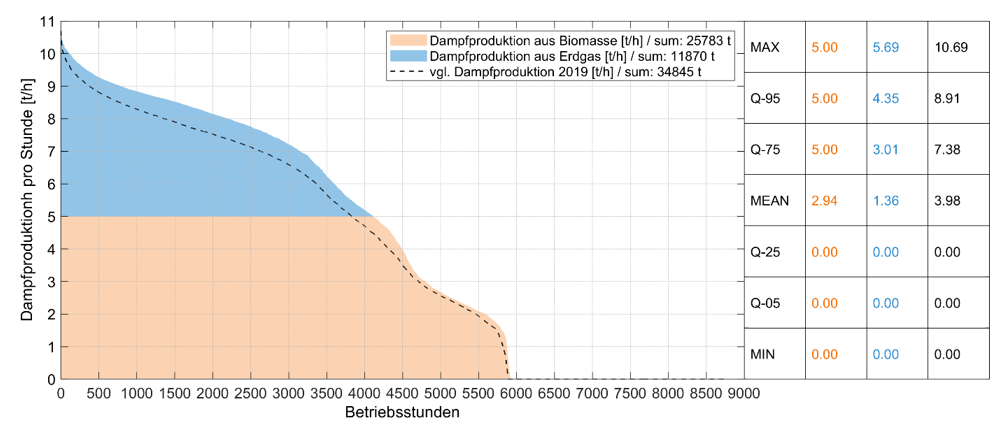

The illustration shows that the future power curve will ultimately be covered by a bivalent biomass boiler-gas boiler system.

The rough dimensioning of the steam production that can be covered by the biomass boiler derived from the simulation is at a nominal load design of 5 t/h nominal saturated steam output, as illustrated in the following diagram. Since in this bivalent system for steam production a large part of the demand is covered with biomass instead of fossil gas, this massively reduces the emitted CO2.